Jun . 14, 2024 10:00

Back to list

Welded wire mesh's tensile strength

Understanding the Strength of Welded Wire Mesh An Essential Element in Construction and Industry

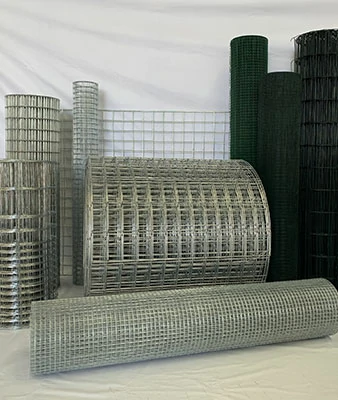

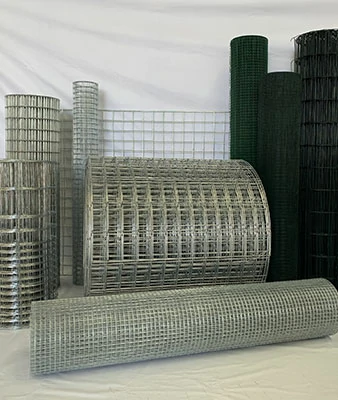

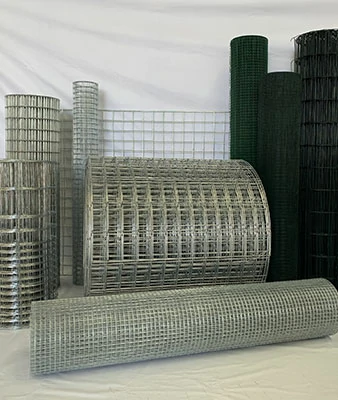

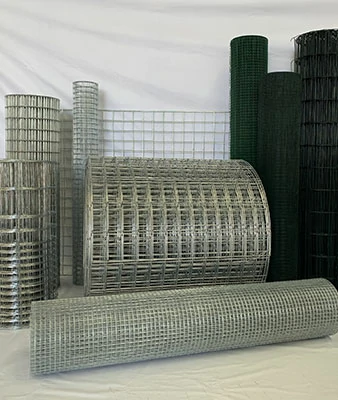

Welded wire mesh, a versatile and robust material, plays a pivotal role in various industries due to its inherent strength and durability. This intricate lattice of crossed wires, welded at their intersections, offers a unique combination of properties that make it an indispensable component in construction, agriculture, and manufacturing.

The strength of welded wire mesh is primarily derived from its manufacturing process. It is created by welding individual steel wires together at their intersection points, forming a grid pattern. The wires are usually made from high-quality carbon steel or stainless steel, which already possess significant tensile strength. The welding process not only binds these wires securely but also enhances the overall structural integrity of the mesh.

The strength of the welded wire mesh is measured in terms of its tensile strength, yield strength, and deformation resistance. Tensile strength refers to the maximum stress a material can withstand before breaking, while yield strength denotes the point at which it begins to deform permanently. Welded wire mesh typically exhibits high tensile and yield strengths, allowing it to endure substantial loads without deformation or failure.

In construction, the strength of welded wire mesh is crucial for reinforcing concrete structures. It provides additional support, distributing loads evenly and resisting cracking. The mesh's rigidity and stability enhance the structural integrity of floors, walls, and foundations, making it a preferred choice in architectural designs.

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts welded wire mesh strength. Its resistance to deformation makes it effective in deterring intrusion attempts and providing a sturdy barrier. Moreover, in agricultural settings, welded wire mesh is employed for animal enclosures, ensuring safety while withstanding the force exerted by livestock.

The weld quality significantly influences the strength of the wire mesh. A strong and consistent weld ensures that the wires remain interconnected even under extreme conditions. Regular quality checks and adherence to industry standards guarantee the reliability and longevity of the mesh.

Furthermore, the gauge or diameter of the wires used in the mesh also impacts its strength. Thicker wires generally result in a stronger mesh, suitable for heavy-duty applications, whereas thinner wires provide a more flexible option for lighter tasks.

In conclusion, the strength of welded wire mesh lies in its manufacturing process, material composition, and the quality of the welds. Its robustness, versatility, and resistance to deformation make it an essential element in numerous sectors. Whether it's supporting concrete structures, providing security, or facilitating agricultural operations, the strength of welded wire mesh consistently proves its worth as a reliable and durable material.

welded wire mesh strength. Its resistance to deformation makes it effective in deterring intrusion attempts and providing a sturdy barrier. Moreover, in agricultural settings, welded wire mesh is employed for animal enclosures, ensuring safety while withstanding the force exerted by livestock.

The weld quality significantly influences the strength of the wire mesh. A strong and consistent weld ensures that the wires remain interconnected even under extreme conditions. Regular quality checks and adherence to industry standards guarantee the reliability and longevity of the mesh.

Furthermore, the gauge or diameter of the wires used in the mesh also impacts its strength. Thicker wires generally result in a stronger mesh, suitable for heavy-duty applications, whereas thinner wires provide a more flexible option for lighter tasks.

In conclusion, the strength of welded wire mesh lies in its manufacturing process, material composition, and the quality of the welds. Its robustness, versatility, and resistance to deformation make it an essential element in numerous sectors. Whether it's supporting concrete structures, providing security, or facilitating agricultural operations, the strength of welded wire mesh consistently proves its worth as a reliable and durable material.

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts

In industrial applications, such as fencing or security barriers, the strength of the mesh is vital for withstanding external forces and impacts welded wire mesh strength. Its resistance to deformation makes it effective in deterring intrusion attempts and providing a sturdy barrier. Moreover, in agricultural settings, welded wire mesh is employed for animal enclosures, ensuring safety while withstanding the force exerted by livestock.

The weld quality significantly influences the strength of the wire mesh. A strong and consistent weld ensures that the wires remain interconnected even under extreme conditions. Regular quality checks and adherence to industry standards guarantee the reliability and longevity of the mesh.

Furthermore, the gauge or diameter of the wires used in the mesh also impacts its strength. Thicker wires generally result in a stronger mesh, suitable for heavy-duty applications, whereas thinner wires provide a more flexible option for lighter tasks.

In conclusion, the strength of welded wire mesh lies in its manufacturing process, material composition, and the quality of the welds. Its robustness, versatility, and resistance to deformation make it an essential element in numerous sectors. Whether it's supporting concrete structures, providing security, or facilitating agricultural operations, the strength of welded wire mesh consistently proves its worth as a reliable and durable material.

welded wire mesh strength. Its resistance to deformation makes it effective in deterring intrusion attempts and providing a sturdy barrier. Moreover, in agricultural settings, welded wire mesh is employed for animal enclosures, ensuring safety while withstanding the force exerted by livestock.

The weld quality significantly influences the strength of the wire mesh. A strong and consistent weld ensures that the wires remain interconnected even under extreme conditions. Regular quality checks and adherence to industry standards guarantee the reliability and longevity of the mesh.

Furthermore, the gauge or diameter of the wires used in the mesh also impacts its strength. Thicker wires generally result in a stronger mesh, suitable for heavy-duty applications, whereas thinner wires provide a more flexible option for lighter tasks.

In conclusion, the strength of welded wire mesh lies in its manufacturing process, material composition, and the quality of the welds. Its robustness, versatility, and resistance to deformation make it an essential element in numerous sectors. Whether it's supporting concrete structures, providing security, or facilitating agricultural operations, the strength of welded wire mesh consistently proves its worth as a reliable and durable material. Share

Latest news

-

Space-Saving Chain Fence Hacks Vertical Gardening with Cyclone MeshNewsJul.16,2025

-

Innovations in Iron Nail Wire Production for Modern ConstructionNewsJul.16,2025

-

Creative Uses of Wire Netting Fence in Modern Landscape DesignNewsJul.16,2025

-

Barbed Wire Fence Innovations in Anti-Climb TechnologyNewsJul.16,2025

-

Architectural Uses of Umbrella Nails for Aesthetic Roof DesignsNewsJul.16,2025

-

Architectural Uses of Razor Barbed Wire in Secure Urban DesignNewsJul.16,2025