Jun . 13, 2024 12:26

Back to list

Untreated steel wire mesh

Understanding Non-Galvanized Wire Mesh A Comprehensive Overview

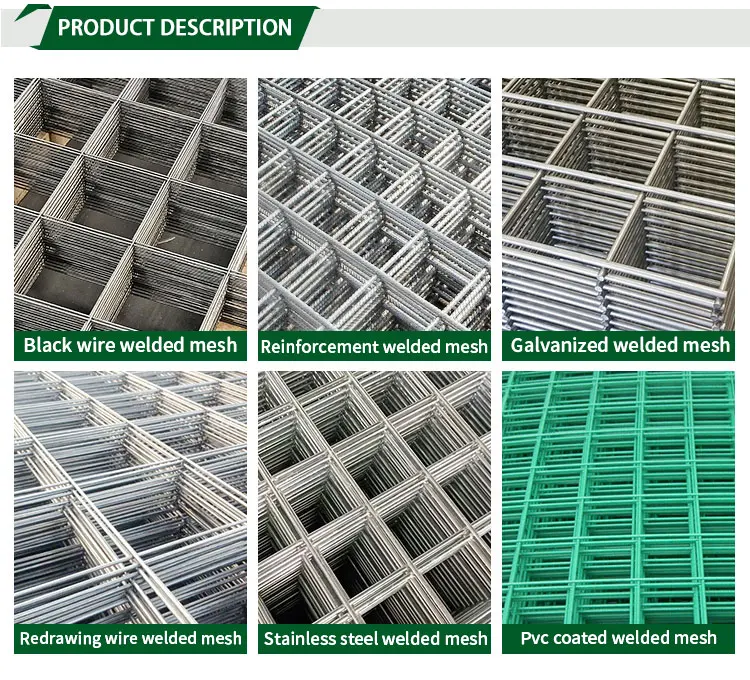

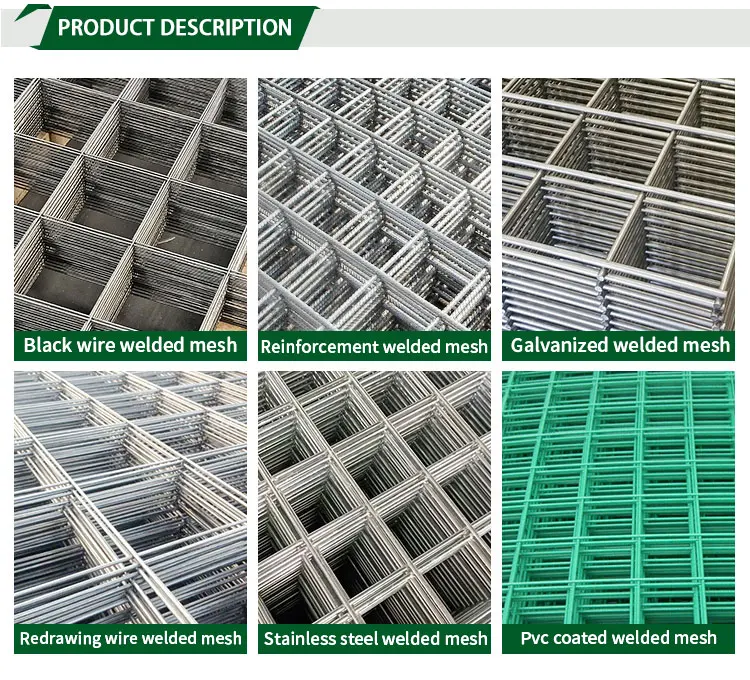

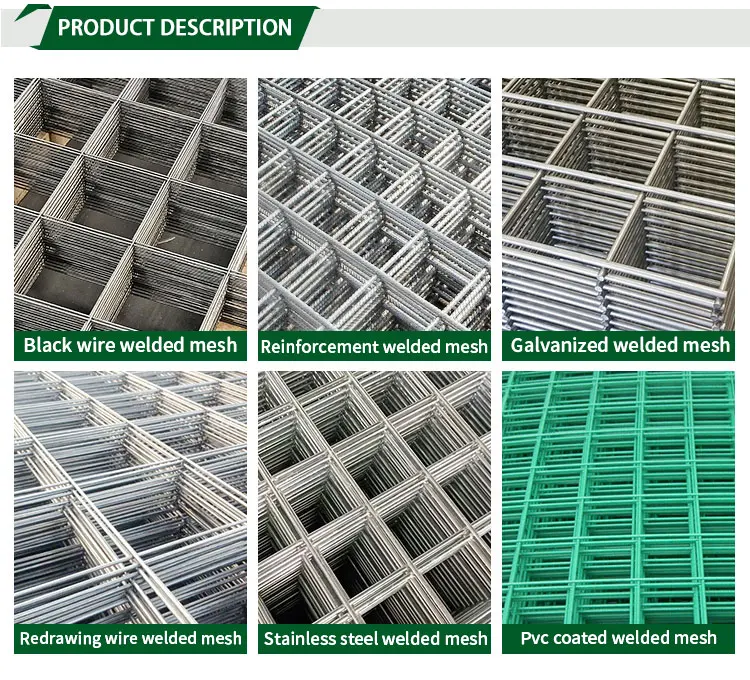

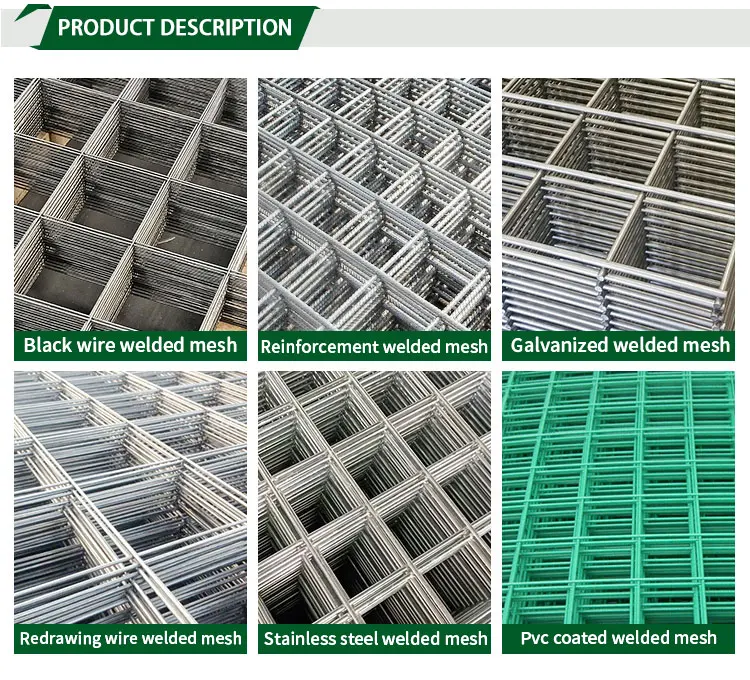

Non-galvanized wire mesh, also known as plain steel wire mesh, is a versatile and widely used material in various industries due to its durability and cost-effectiveness. This type of wire mesh is made from steel wires that have not undergone the galvanization process, which involves coating the wire with a layer of zinc to protect against corrosion.

The fabrication of non-galvanized wire mesh begins with the selection of high-quality steel wires. These wires are then woven or welded together to create a grid-like structure, forming a mesh pattern. The size and spacing of the wires can vary greatly, catering to different applications and requirements. The absence of a protective coating makes it more affordable compared to its galvanized counterpart, but it also means it may be more susceptible to rust and wear over time.

One primary use of non-galvanized wire mesh lies in construction. It serves as a reinforcement material in concrete structures, providing additional strength and stability. In agriculture, it's employed for fencing and animal enclosures due to its robustness and ability to withstand pressure. Additionally, it's commonly used in filtration systems, where its open structure allows for the passage of liquids or gases while retaining solid particles.

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings non galvanised wire mesh. It's used in manufacturing processes for sieving and screening materials, such as in mining and quarrying operations. In the arts and crafts sector, its malleability and versatility make it a popular choice for sculptures, installations, and even jewelry making.

However, the lack of galvanization requires careful consideration in environments exposed to moisture or harsh weather conditions. Regular maintenance and protective treatments like painting or oiling can extend its lifespan and prevent premature rusting. Alternatively, stainless steel wire mesh, although more expensive, can be a suitable alternative for applications requiring higher resistance to corrosion.

In conclusion, non-galvanized wire mesh, despite its potential vulnerabilities, remains a staple material across multiple industries due to its adaptability, affordability, and the range of sizes and configurations available. Its usage underscores the importance of balancing functionality with cost efficiency in various projects. Understanding the specific needs and conditions of each application is crucial in determining whether non-galvanized wire mesh is the right choice.

non galvanised wire mesh. It's used in manufacturing processes for sieving and screening materials, such as in mining and quarrying operations. In the arts and crafts sector, its malleability and versatility make it a popular choice for sculptures, installations, and even jewelry making.

However, the lack of galvanization requires careful consideration in environments exposed to moisture or harsh weather conditions. Regular maintenance and protective treatments like painting or oiling can extend its lifespan and prevent premature rusting. Alternatively, stainless steel wire mesh, although more expensive, can be a suitable alternative for applications requiring higher resistance to corrosion.

In conclusion, non-galvanized wire mesh, despite its potential vulnerabilities, remains a staple material across multiple industries due to its adaptability, affordability, and the range of sizes and configurations available. Its usage underscores the importance of balancing functionality with cost efficiency in various projects. Understanding the specific needs and conditions of each application is crucial in determining whether non-galvanized wire mesh is the right choice.

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings

Non-galvanized wire mesh also finds its way into industrial settings non galvanised wire mesh. It's used in manufacturing processes for sieving and screening materials, such as in mining and quarrying operations. In the arts and crafts sector, its malleability and versatility make it a popular choice for sculptures, installations, and even jewelry making.

However, the lack of galvanization requires careful consideration in environments exposed to moisture or harsh weather conditions. Regular maintenance and protective treatments like painting or oiling can extend its lifespan and prevent premature rusting. Alternatively, stainless steel wire mesh, although more expensive, can be a suitable alternative for applications requiring higher resistance to corrosion.

In conclusion, non-galvanized wire mesh, despite its potential vulnerabilities, remains a staple material across multiple industries due to its adaptability, affordability, and the range of sizes and configurations available. Its usage underscores the importance of balancing functionality with cost efficiency in various projects. Understanding the specific needs and conditions of each application is crucial in determining whether non-galvanized wire mesh is the right choice.

non galvanised wire mesh. It's used in manufacturing processes for sieving and screening materials, such as in mining and quarrying operations. In the arts and crafts sector, its malleability and versatility make it a popular choice for sculptures, installations, and even jewelry making.

However, the lack of galvanization requires careful consideration in environments exposed to moisture or harsh weather conditions. Regular maintenance and protective treatments like painting or oiling can extend its lifespan and prevent premature rusting. Alternatively, stainless steel wire mesh, although more expensive, can be a suitable alternative for applications requiring higher resistance to corrosion.

In conclusion, non-galvanized wire mesh, despite its potential vulnerabilities, remains a staple material across multiple industries due to its adaptability, affordability, and the range of sizes and configurations available. Its usage underscores the importance of balancing functionality with cost efficiency in various projects. Understanding the specific needs and conditions of each application is crucial in determining whether non-galvanized wire mesh is the right choice. Share

Latest news

-

Successful Participation at the 137th Canton Fair in April 2025NewsApr.20,2025

-

Successful Participation at the 2025 NAHB International Builders' Show (IBS) in Las VegasNewsFeb.28,2025

-

Successful Participation at the 2025 Philippine World Building and Construction Exposition (WorldBex) in ManilaNewsMar.20,2024

-

Successful Participation at the 2024 Canton FairsNewsOct.20,2024

-

Successful Participation at the 2024 Canton FairNewsApr.20,2024

-

Successful Participation at the 2024 Philippine World Building and Construction Exposition in ManilaNewsMar.20,2024