Choosing the Best Chicken Wire Fencing for Your Home Garden Needs******Chicken Wire Fencing for Your Garden A Practical Solution for Garden Protection When it comes to gardening, protecting your precious plants from potential threats is of utmost importance. From curious pets to hungry wildlife, a variety of critters could undermine your gardening efforts if left unchecked. This is where chicken wire fencing comes into play—a versatile and cost-effective solution that has gained popularity among garden enthusiasts. What is Chicken Wire Fencing? Chicken wire, also known as poultry netting, is a type of fencing made from thin, flexible wire woven into a grid pattern, usually with hexagonal openings. Traditionally used for enclosing chickens, it has found multiple applications in landscaping, gardening, and agriculture due to its durability and affordability. The mesh is lightweight and easy to work with, making it an ideal choice for gardeners looking to create a barrier without breaking the bank. Benefits of Using Chicken Wire for Your Garden 1. Cost-Effective Protection One of the primary advantages of chicken wire is its affordability. Compared to solid fencing or elaborate setups, chicken wire provides a budget-friendly option that doesn’t compromise on effectiveness. This can be especially advantageous for gardeners on a tight budget or those just starting. 2. Versatility Chicken wire can be used for multiple purposes in the garden. It can create barriers around vegetable patches, flower beds, or even entire gardens. It can also be fashioned into garden trellises, plant supports, or even decorative elements to enhance the garden's aesthetic. 3. Ease of Installation Installing chicken wire is a straightforward process, making it accessible for those who might not have extensive DIY experience. With just a few essential tools—such as wire cutters, gloves, and stakes—anyone can create a reliable fence in a matter of hours. 4. Visibility and Light Penetration Unlike solid fences, chicken wire is transparent, allowing sunlight and rain to reach your plants without obstruction . This feature is particularly beneficial for plants that need ample light to thrive, ensuring that your garden remains vibrant and healthy. chicken wire fencing for garden 5. Heavy-Duty Protection Against Small Animals Chicken wire is an excellent deterrent for small animals like rabbits, squirrels, and birds that pose a threat to young plants. The mesh’s hexagonal openings are typically small enough to prevent these pests from accessing your garden while also keeping it visually appealing. Installation Tips for Chicken Wire Fencing 1. Choose the Right Height The height of your chicken wire fence should depend on what you aim to protect. For smaller animals, a fence that is three to four feet tall might suffice. However, if deer or larger animals are a concern, consider building a taller fence. 2. Bury the Bottom Edge To prevent animals from digging underneath the fence, bury the bottom edge of the chicken wire. A depth of 6-12 inches can greatly enhance the barrier’s effectiveness. 3. Secure the Posts Use sturdy wooden or metal stakes to secure the chicken wire in place. Make sure to space the posts adequately to provide enough support without sagging. 4. Monitor Regularly Even with a sturdy fence, it’s important to regularly check for damage or wear. Over time, the elements can weaken the wire, and predators may find creative ways to enter. Conclusion Chicken wire fencing serves as an excellent solution for garden protection, providing a practical, versatile, and economical way to keep your plants safe from unwanted intruders. By investing a little time and effort into the installation, you can enjoy a flourishing garden without the worry of critters ruining your hard work. Whether you have a small vegetable patch or a sprawling flower garden, chicken wire can be the guardian you need to ensure your garden thrives. With proper care and maintenance, your chicken wire fence can stand the test of time, allowing you to focus on what truly matters—growing and enjoying your garden._nice wire fence

Innovative Razor Wire Solutions for Enhanced Security and Perimeter Protection

The Intersection of Razor, Blade, and Barbed Wire A Study in Security and Design In the realm of sec...

Aidan kirkastaminen ja langan tiukentaminen tehokkaasti ja turvallisesti.

Tiukkana pysyvänä Aitaustankojen tiukentaminen Aitaus on olennainen osa monia maatalous- ja eläintal...

Durable and Effective Barbed Wire Fencing Solutions for Secure Perimeters and Livestock Protection

The Benefits and Uses of Sharp Wire Fences Sharp wire fences have long been a practical solution for...

fence wire gauge

Understanding Fence Wire Gauge A Practical Guide When it comes to fencing, selecting the right mater...

Cost Breakdown for Installing Chain Link Fences and Key Considerations

Understanding the Installation Costs of Chain Link Fencing Chain link fencing is one of the most pop...

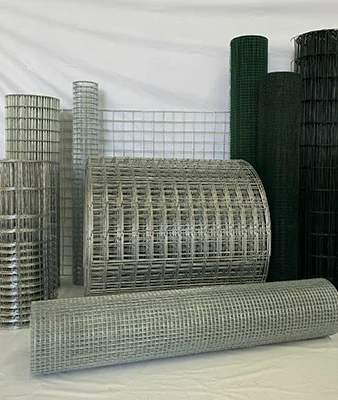

Exploring Various Sizes and Specifications of Wire Welded Mesh for Industrial Applications

Understanding Wire Welded Mesh Sizes A Comprehensive Guide Wire welded mesh is an essential material...

Conclusion

...

One of the standout features of black coated wire fences is their durability. These fences are typically made of high-quality galvanized steel wire, which is designed to withstand the elements. The black powder coating not only enhances the lifespan of the fence by providing a barrier against rust and corrosion but also minimizes the need for maintenance over time. This durability makes them a cost-effective option, as they require fewer replacements, repairs, and maintenance efforts compared to other fencing types.

...

Links

- Durable Mesh Fencing Solutions for Enhanced Security and Longevity******Heavy Duty Mesh Fencing A Robust Solution for Security and Privacy In today's world, ensuring safety and privacy has become a paramount concern for both residential and commercial properties. One effective solution that has gained popularity is heavy duty mesh fencing. This type of fencing is not only sturdy but also versatile, making it an ideal choice for various applications, including construction sites, industrial complexes, and private homes. Heavy duty mesh fencing is designed to withstand harsh conditions and provide a high level of security. Made from strong materials such as galvanized steel or welded wire, it is engineered to resist corrosion, weather damage, and physical attacks. This resilience makes it particularly suitable for areas that require robust protection, such as warehouses and government facilities. One of the standout features of mesh fencing is its visibility. Unlike solid panel fencing that can create an enclosure that feels closed off, heavy duty mesh fencing maintains an open view of the surrounding area. This transparency not only helps deter potential intruders, who may be less likely to target areas that are easily visible, but it also allows property owners to monitor their surroundings effectively. This is particularly beneficial for businesses that require oversight of their premises. heavy duty mesh fencing In addition to security, heavy duty mesh fencing is also a cost-effective option. Its durable construction means that it often requires less maintenance over time compared to traditional wooden or vinyl fencing . Property owners can enjoy peace of mind knowing that they made a wise investment in a solution that will stand the test of time. Moreover, heavy duty mesh fencing can be customized to meet specific needs. Available in various heights, styles, and finishes, it can be tailored to suit the aesthetic preferences of any property while still providing top-notch security. Whether for a park, industrial site, or a private residence, there is a suitable design that can complement the surroundings. Installing heavy duty mesh fencing is a straightforward process that typically requires minimal disruption. Most installations can be completed quickly, allowing property owners to benefit from enhanced security without a lengthy wait. In conclusion, heavy duty mesh fencing offers a dynamic solution for those looking to enhance security and privacy. Its combination of durability, visibility, cost-effectiveness, and customization makes it an appealing choice for a variety of applications. As safety remains a priority in our communities, investing in such robust fencing is a proactive step toward safeguarding properties for years to come.

- Filo spinato in acciaio inossidabile per sicurezza e protezione resistente agli agenti atmosferici******Il filo spinato in acciaio inox una soluzione duratura e sicura Il filo spinato in acciaio inox rappresenta una delle soluzioni più efficaci per la sicurezza e la protezione di spazi pubblici e privati. La combinazione di robustezza, resistenza alla corrosione e durata nel tempo rende questo materiale particolarmente adatto per diverse applicazioni, tra cui recinzioni, impianti industriali e aree residenziali. Il filo spinato in acciaio inox una soluzione duratura e sicura Un altro aspetto importante da considerare è l'efficacia del filo spinato in termini di sicurezza. La sua struttura appuntita e affilata funge da deterrente visivo e fisico, rendendo più difficile l'accesso non autorizzato a proprietà private o aree sensibili. Questo tipo di protezione è particolarmente utile in contesti come carceri, installazioni militari, centri di produzione e aree isolate, dove la sicurezza è una priorità assoluta. stainless steel barbed wire Inoltre, il design del filo spinato in acciaio inox può variare a seconda delle esigenze specifiche del cliente. Esistono diversi tipi di filo spinato, come il filo spinato classico, il filo spinato a spirale e il filo spinato elettrificato, ognuno dei quali offre soluzioni diverse per questioni di sicurezza. Il filo spinato può essere installato in modo da integrarsi armoniosamente con altri sistemi di sicurezza, come telecamere di sorveglianza e allarmi, creando un sistema di protezione completo ed efficace. Oltre alla funzionalità, l'estetica gioca un ruolo importante, soprattutto in contesti residenziali o in aree pubbliche. L'acciaio inox può essere aggiunto in modo da armonizzarsi con l'ambiente circostante, mantenendo un aspetto elegante e professionale. Ciò lo rende una scelta popolare non solo per la sicurezza, ma anche per il design architettonico. Infine, è importante considerare l'impatto ambientale del materiale utilizzato. L'acciaio inox è riciclabile, il che significa che una volta raggiunta la fine della sua vita utile, può essere riutilizzato per creare nuovi prodotti, riducendo così l'impatto ambientale. Scegliere il filo spinato in acciaio inox non significa solo optare per un prodotto di alta qualità, ma anche contribuire a una gestione più sostenibile delle risorse. In conclusione, il filo spinato in acciaio inox offre numerosi vantaggi rispetto ad altre soluzioni di sicurezza. La sua durabilità, resistenza, versatilità e sostenibilità lo rendono una scelta ideale per chi cerca una protezione efficace e duratura per i propri spazi. Che si tratti di una proprietà privata o di un’installazione industriale, il filo spinato in acciaio inox si conferma una soluzione di fiducia e di alto livello.

- Hexagonal Gabion A Sustainable and Versatile Solution for Erosion Control******Hexagonal Gabion A Versatile Solution for Erosion Control and Landscaping Hexagonal gabions, a type of wire mesh container filled with rocks or other materials, have become increasingly popular in recent years due to their versatility and effectiveness in various engineering applications. These uniquely shaped structures offer numerous benefits over traditional rectangular gabions, making them an ideal choice for both erosion control and landscaping projects. One of the primary advantages of hexagonal gabions is their ability to interlock seamlessly, creating a stable and continuous barrier against soil erosion. This interlocking feature allows for greater flexibility in design, as the hexagonal shape can be arranged in a variety of patterns to suit the specific needs of a project. Additionally, the open structure of the wire mesh allows water to flow through freely, reducing hydrostatic pressure on the structure and promoting the growth of vegetation within the gabion. In terms of erosion control, hexagonal gabions are particularly effective at stabilizing slopes and preventing soil loss along riverbanks, coastal areas, and other vulnerable terrains. By providing a strong and permeable barrier, these structures help to slow down the velocity of water flow, thereby reducing its erosive power. The weight and mass of the rock-filled gabions also contribute to their stability, ensuring that they remain firmly in place even under severe weather conditions. Moreover, hexagonal gabions offer significant aesthetic appeal when used in landscaping projects Moreover, hexagonal gabions offer significant aesthetic appeal when used in landscaping projects Moreover, hexagonal gabions offer significant aesthetic appeal when used in landscaping projects Moreover, hexagonal gabions offer significant aesthetic appeal when used in landscaping projects hexagonal gabion . Their natural stone filling creates a pleasing visual texture that blends well with surrounding environments, while the geometric shape adds an interesting element of design. They can be used to create retaining walls, garden features, or even seating areas, enhancing both the functionality and beauty of outdoor spaces. The installation process for hexagonal gabions is relatively simple and straightforward, requiring minimal equipment and labor. Once installed, these structures require little maintenance beyond regular inspections to ensure that the filling material remains secure within the wire mesh enclosure. In conclusion, hexagonal gabions represent a practical and attractive solution for addressing erosion control challenges and enhancing landscape designs. With their interlocking capability, permeability, and aesthetic qualities, they offer a versatile option that combines functionality with visual appeal. As such, they continue to gain popularity among engineers, landscapers, and environmentalists seeking sustainable solutions for managing natural resources and improving our living environments.

- Durable Galvanized Metal Mesh for Various Applications in Construction and Fabrication Industries******Understanding Galvanised Metal Mesh Properties, Applications, and Benefits Galvanised metal mesh is a versatile material that has become increasingly popular across various industries due to its durability, strength, and resistance to corrosion. The term galvanised refers to a process in which steel or iron is coated with a layer of zinc to protect it from rust and environmental factors. This protective coating makes galvanised metal mesh an ideal choice for numerous applications, ranging from construction to agriculture. Properties of Galvanised Metal Mesh One of the standout features of galvanised metal mesh is its remarkable resistance to corrosion. The zinc coating acts as a barrier between the base metal and the external environment, significantly prolonging its lifespan. This property is particularly beneficial in outdoor applications where exposure to moisture, sunlight, and other elements is unavoidable. Additionally, galvanised metal mesh exhibits excellent strength-to-weight ratio, making it sturdy yet lightweight, which allows for easy handling and installation. Another important attribute of galvanised metal mesh is its versatility in manufacturing. It can be produced in various sizes, patterns, and wire gauges, making it suitable for diverse needs. Whether it's for fencing, screening, or as a component in machinery, the customisable nature of galvanised metal mesh ensures that it can meet specific requirements efficiently. Applications of Galvanised Metal Mesh Galvanised metal mesh finds its applications in numerous fields. In construction, it is commonly used as a reinforcement mesh in concrete, providing additional strength and stability to structures. Furthermore, it serves as a safety barrier, preventing accidents and ensuring the security of construction sites. galvanised metal mesh In agriculture, galvanised metal mesh is extensively utilized for fencing livestock, keeping them safe while allowing for airflow and visibility. It is also used in greenhouses, as it supports plants while providing necessary drainage. The mesh's corrosion resistance is particularly advantageous in farming, where exposure to fertilizers and chemicals can otherwise damage unprotected materials. The mining and industrial sectors also benefit significantly from galvanised metal mesh. It is commonly used to create safety screens, control dust, and as a medium for sorting materials. Its durability and resistance to harsh environments make it a preferred choice in these rigorous applications. Benefits of Galvanised Metal Mesh Investing in galvanised metal mesh offers several benefits. Firstly, the longevity of this material means reduced replacement and maintenance costs over time. The zinc coating can last for several decades if properly maintained, making it a cost-effective solution overall. Moreover, galvanised metal mesh is eco-friendly. The materials used in the galvanization process are recyclable, contributing to sustainable practices in manufacturing. Additionally, the mesh’s robust design minimizes the need for additional support structures, which can help reduce material waste. In conclusion, galvanised metal mesh is a powerful product that provides a plethora of benefits across multiple industries. Its corrosion resistance, versatility, and strength make it an essential material in construction, agriculture, and industrial applications. As companies continue to seek durable and cost-efficient solutions, the demand for galvanised metal mesh is likely to grow, making it a staple in modern manufacturing and infrastructure projects. Whether you are looking to reinforce a structure, create agricultural fencing, or enhance safety in industrial settings, galvanised metal mesh offers a reliable and effective solution.

- Durable PVC Coated Chicken Wire for Secure Fencing and Animal Enclosures in Various Applications******Exploring the Benefits and Applications of PVC Chicken Mesh In the realm of agricultural and gardening practices, one of the most versatile and effective materials that have gained immense popularity is PVC chicken mesh. As the name suggests, this is a type of netting that is primarily used for poultry enclosures, but its applications stretch far beyond just housing chickens. This article delves into the various benefits and uses of PVC chicken mesh, showcasing why it has become a favored choice among poultry farmers, gardeners, and a variety of DIY enthusiasts. PVC chicken mesh, often referred to as poultry netting, is made from durable plastic-coated wire. The PVC coating provides a high level of protection against the elements, ensuring that the mesh retains its integrity over time. This durability is one of the primary advantages of using PVC chicken mesh. Unlike traditional galvanized wire, which can rust or corrode when exposed to moisture, PVC chicken mesh is waterproof and resistant to both UV rays and harsh weather conditions. As a result, it proves to be a long-lasting investment for anyone looking to protect their livestock and plants. Exploring the Benefits and Applications of PVC Chicken Mesh For poultry farmers, the benefits of using PVC chicken mesh are numerous. It provides a secure and safe environment for chickens while allowing for adequate airflow. Proper ventilation is crucial for maintaining a healthy environment in chicken coops, and the mesh allows for air circulation while keeping the birds confined. Moreover, the visual transparency of the mesh enables farmers to monitor their flocks easily, ensuring that all chickens are accounted for. pvc chicken mesh In addition to its functionality for poultry, PVC chicken mesh also serves as an effective barrier against garden pests. Many gardeners face challenges from rabbits, deer, and other animals that threaten their crops. By surrounding gardens with PVC chicken mesh, they can create a protective barrier that deters these animals without the need for harmful chemicals or complicated fencing solutions. The mesh is also effective against insects, as it can be installed in a way that covers plants without hindering their growth. Another significant advantage of PVC chicken mesh is its affordability. Compared to other fencing materials such as wood or metal, PVC chicken mesh presents a cost-effective solution without sacrificing quality. This affordability makes it accessible to small-scale farmers and hobbyists alike, allowing them to invest in high-quality infrastructure while keeping costs under control. Furthermore, the eco-friendly nature of PVC is an appealing aspect for environmentally-conscious individuals. The longevity of PVC chicken mesh means less frequent replacements, leading to reduced waste. It is also recyclable, contributing to sustainable practices in both agriculture and gardening. In conclusion, PVC chicken mesh offers a myriad of benefits that make it a valuable asset for anyone involved in poultry farming, gardening, or DIY projects. Its durability, ease of installation, versatility, affordability, and eco-friendly properties position it as a superior choice in fencing and enclosures. As more individuals and businesses recognize the advantages of PVC chicken mesh, it is likely to become a staple in agricultural practices, promoting both productivity and sustainability in our gardens and farms.

- Harnessing Sight for Horses to Enhance Training and Performance in Equestrian Sports******Understanding the Sighter Wire for Horses A Comprehensive Guide The world of equestrianism is rich with terminology and specialized equipment, each designed to enhance the relationship between horse and rider. Among these is the sighter wire, a tool that has garnered attention, especially in the realm of horse training and competitions. In this article, we’ll explore what the sighter wire is, its uses, benefits, and how it can improve both horse and rider performance. What is Sighter Wire? Sighter wire is typically a thin, flexible wire or cord that can be installed in various equestrian settings, such as arenas or obstacle courses. Its primary purpose is to provide a visual guide for horses, helping them navigate through obstacles or specific paths. The sighter wire serves as a marker that the horse can see, making it easier for them to understand where they are supposed to go, thereby minimizing confusion during training and competition. Uses of Sighter Wire The sighter wire can be utilized in a multitude of ways across different riding disciplines. In show jumping, for example, it might be used to outline the intended path a horse should take during a round. Riders can instruct their horses to follow the wire, ensuring that they maintain the correct trajectory toward each jump. In dressage, sighter wires can help establish the boundaries of the arena or delineate specific patterns that need to be executed during a test. By having clear visual markers, both horse and rider can develop a better understanding of the spatial requirements of the movements being performed. Additionally, the sighter wire can be a useful tool during groundwork . When teaching horses to respond to various cues, the wire provides a constant point of reference, allowing trainers to reinforce learning and ensure consistency. Benefits of Sighter Wire sighter wire for horses 1. Improved Clarity One of the most significant advantages of sighter wire is the clarity it provides. Horses, being visual learners, can benefit from having a clear line that aids them in understanding the intended path. This reduces the likelihood of miscommunication between rider and horse. 2. Enhanced Performance For competitive riders, the sighter wire can contribute to improved performance across various disciplines. By guiding horses accurately, riders can achieve smoother transitions and more precise movements, leading to higher scores in competitions. 3. Confidence Building Both horses and riders can experience an increase in confidence when using sighter wires. Horses become more secure in their movements when they have a visual target to follow, while riders can focus more on their technique, knowing that their horse is following the intended path. 4. Increased Safety In training sessions, particularly those involving jumping or complex movements, the sighter wire can create a safer environment. By reducing the risk of misinterpretation, both horse and rider can navigate obstacles with greater assurance, minimizing the chance of falls or accidents. Considerations When Using Sighter Wire While the sighter wire offers numerous advantages, there are also important considerations to keep in mind. Firstly, it is essential to ensure that the wire is visible and secure, preventing any potential accidents. Additionally, the training method associated with the sighter wire should be gradual and patient; forcing a horse to follow the wire without adequate guidance may lead to anxiety rather than confidence. Moreover, trainers should remain aware of each horse's individual temperament and learning style. Some horses may respond exceptionally well to visual cues, while others might need more auditory or tactile guidance. Therefore, incorporating the sighter wire should be part of a broader, more comprehensive training strategy. Conclusion The sighter wire is a valuable tool within the equestrian world, promoting better communication between horse and rider. By offering a clear visual guide, it enhances performance, builds confidence, and increases safety in training and competitions. As with any training aid, it is most effective when used thoughtfully and in conjunction with a well-rounded approach to horse education. Ultimately, the key to success lies in understanding the unique needs of each horse and utilizing the sighter wire as a means of fostering a stronger partnership built on trust and clarity.

- Green privacy mesh for fence screening******Enhancing Privacy with Green The Appeal of Green Privacy Mesh for Fences In today's world, where personal space and privacy are increasingly cherished commodities, the role of fencing solutions has evolved beyond mere boundaries. Among the various options available, green privacy mesh for fences has emerged as a popular choice, blending practicality with an aesthetic appeal that harmonizes with nature. Green privacy mesh, as the name suggests, is a type of fence covering made from synthetic materials, often featuring a verdant hue to mimic natural foliage. It serves a dual purpose - providing seclusion while adding a touch of greenery to the surroundings. This innovative solution is not only functional but also environmentally conscious, reflecting our growing commitment to sustainability. One of the key advantages of green privacy mesh is its ability to offer instant privacy without obstructing light or air circulation. Its open-weave design allows sunlight and breeze to pass through, creating a comfortable microclimate around the fence. Moreover, the green color helps it blend seamlessly into landscapes, reducing visual impact and enhancing the overall aesthetics of the property. The durability of green privacy mesh is another significant factor contributing to its popularity. Made from high-quality, UV-resistant materials, it can withstand harsh weather conditions, ensuring long-term use Made from high-quality, UV-resistant materials, it can withstand harsh weather conditions, ensuring long-term use Made from high-quality, UV-resistant materials, it can withstand harsh weather conditions, ensuring long-term use Made from high-quality, UV-resistant materials, it can withstand harsh weather conditions, ensuring long-term use green privacy mesh for fences . Its lightweight nature makes installation quick and easy, requiring minimal maintenance over time. Furthermore, this privacy mesh is versatile, adaptable to different fence types and heights, making it suitable for residential, commercial, or even public spaces. It can be used to screen off patios, gardens, swimming pools, or even construction sites, offering a cost-effective and eco-friendly alternative to traditional solid fencing. Beyond its functional benefits, green privacy mesh also fosters a sense of community by maintaining a connection with the outdoors while preserving individual privacy. It promotes a greener environment by reducing the need for additional plants or hedges that might consume more water and resources. In conclusion, green privacy mesh for fences is a modern, practical, and eco-friendly solution that combines privacy, aesthetics, and sustainability. As we strive for a balance between personal space and environmental responsibility, this innovative mesh emerges as a smart choice for those seeking to enhance their living spaces. It not only respects the need for privacy but also contributes to the beauty and health of our environment, making it a win-win proposition in the realm of fencing solutions.

- German concertina wire******The Role of German Barbed Wire in World War I German barbed wire, an unassuming yet formidable tool of warfare, played a significant and often underestimated role in the First World War. Its introduction transformed the nature of combat, turning vast stretches of the Western Front into impenetrable barriers that slowed down, if not halted, the advance of armies. Barbed wire, or Stacheldraht as it was known in German, was first developed in the United States in the mid-19th century for agricultural purposes. However, its military potential was quickly recognized by the German army, which incorporated it extensively into their defensive strategies. The German use of barbed wire was revolutionary; they didn't just lay it down, but constructed intricate and complex systems designed to obstruct and confuse enemy troops. The German barbed wire entanglements were not simple linear barriers. Instead, they created a labyrinth of multiple layers, with some sections reinforced with tripwires and mines. These dense networks were strategically placed in front of trenches, creating a 'no man's land' that was almost impossible to cross without being exposed to heavy fire. The wire was often strung low to the ground, making it difficult for soldiers to crawl under, and at intervals, there were 'concertinas' - coiled sections that could spring open and ensnare anyone attempting to cut through. The effectiveness of German barbed wire was first demonstrated during the Battle of Tannenberg in 1914, where it significantly contributed to the decimation of Russian forces The effectiveness of German barbed wire was first demonstrated during the Battle of Tannenberg in 1914, where it significantly contributed to the decimation of Russian forces The effectiveness of German barbed wire was first demonstrated during the Battle of Tannenberg in 1914, where it significantly contributed to the decimation of Russian forces The effectiveness of German barbed wire was first demonstrated during the Battle of Tannenberg in 1914, where it significantly contributed to the decimation of Russian forces german barbed wire . It became a symbol of the stalemate on the Western Front, with battles like the Somme and Passchendaele seeing thousands of lives lost in attempts to breach these seemingly insurmountable barriers. The development of specialized wire-cutting tools and tanks by the Allies eventually allowed them to overcome the barbed wire obstacle. However, by then, the war had already been dragged into a brutal trench warfare that lasted for years. The German barbed wire, therefore, not only served as a physical barrier but also as a metaphor for the immovable deadlock that defined World War I. In conclusion, German barbed wire was more than just a tactical innovation; it was a game-changer in the history of warfare. Its impact on the dynamics of battle, the loss of life, and the psychological toll on soldiers cannot be overstated. It stands as a stark reminder of the brutal efficiency of modern warfare and the lengths to which technology can alter the course of history.

- Explore Various Sizes and Specifications of Galvanized Welded Wire Mesh for Construction Use******Understanding Galvanized Welded Wire Mesh Sizes Galvanized welded wire mesh is an incredibly versatile material used in a wide range of applications, from agricultural settings to industrial use. This mesh is composed of intersecting wires that are welded together, followed by a galvanization process that adds a protective zinc coating. This coating enhances the wire mesh's resistance to corrosion, making it suitable for outdoor use. Understanding the sizes of galvanized welded wire mesh is essential for selecting the right type for your project. Types and Sizes of Galvanized Welded Wire Mesh Galvanized welded wire mesh is available in various sizes, which typically refer to the gauge of the wire and the spacing between the wires. The gauge of the wire indicates its thickness, with lower numbers indicating thicker wires. Common gauges range from 8 to 14, where gauge 8 is about 4.0 mm thick, and gauge 14 is approximately 2.0 mm in thickness. In terms of mesh spacing, it is essential to note that different projects require different mesh openings. Common mesh sizes include 1 inch by 1 inch, 2 inches by 2 inches, and smaller sizes such as ½ inch by ½ inch. The choice of mesh size will depend on the application. For example, a ½ inch mesh is suitable for small animals or plants, while a larger mesh may be used for fencing or industrial applications. Applications of Galvanized Welded Wire Mesh Galvanized welded wire mesh is employed in numerous applications due to its durability and strength. One common use is in fencing. The mesh can be used to create secure boundaries for properties or farms. It can keep livestock in and prevent wild animals from entering. For gardens, smaller mesh sizes can protect plants from pests while allowing sunlight and water to penetrate. In construction, welded wire mesh is often used as reinforcement within concrete. The mesh provides additional strength and durability, helping to prevent cracking and deformation. It's also commonly found in industrial settings, where it can be used for shelving, storage containment, or in the creation of secure enclosures. galvanized welded wire mesh sizes Another significant application of galvanized welded wire mesh is in the production of custom cages and pens for animal husbandry. The mesh's strength protects the animals while providing adequate ventilation, thus promoting their well-being. Choosing the Right Size When choosing the appropriate size of galvanized welded wire mesh, several factors need to be considered 1. Purpose Determine the specific application. Are you fencing, constructing, or using it for cages? Your needs will greatly influence the size choice. 2. Environment Consider the environmental conditions. For areas that are particularly wet or prone to corrosion, opting for a heavier gauge with a good galvanization would be advantageous. 3. Regulations Be aware of any local regulations regarding fencing or construction that may dictate the required size or type of mesh. Conclusion Galvanized welded wire mesh is a valuable resource across many industries due to its durability, strength, and versatility. By understanding the various sizes available, including wire gauge and mesh spacing, individuals and businesses can make informed decisions for their specific projects. By carefully selecting the appropriate size based on the intended use and environmental factors, you can ensure optimal performance and longevity of the mesh in any application.

- Durable and Versatile Cattleman Pro 14G Barbed Wire for Farm and Ranch Fencing Needs******The Cattleman Pro 14G Barbed Wire A Comprehensive Guide When it comes to livestock management and property security, the choice of fencing material is paramount. Among the options available on the market, the Cattleman Pro 14G barbed wire stands out as a superior choice for ranchers and landowners alike. This article delves into the features, benefits, and applications of Cattleman Pro 14G barbed wire, highlighting why it is a preferred option for many farming and ranching operations. Strength and Durability One of the most significant attributes of Cattleman Pro 14G barbed wire is its exceptional strength. Made from high-quality steel, this 14-gauge wire is particularly resilient, capable of withstanding the rigors of outdoor conditions. It is designed to resist rust and corrosion, ensuring that the fencing remains effective for years, even in harsh weather conditions. The durability of this barbed wire makes it an ideal choice for securing pastures and enclosures where livestock roam freely. Enhanced Security Security is a critical concern for anyone managing livestock, and Cattleman Pro 14G barbed wire excels in this area. The barbed design acts as a formidable barrier against intruders and predators, discouraging unwanted access to the property. The sharp barbs, placed at regular intervals along the wire, create a deterrent that protects livestock from external threats. This feature is especially advantageous in areas where wildlife or stray animals can pose a risk to the safety of the herd. Versatile Applications cattleman pro 14g barbed wire Cattleman Pro 14G barbed wire is not limited to simply fencing for cattle. Its versatile design and robust construction make it suitable for a variety of applications. From enclosing cattle and horses to creating boundaries for other livestock, this barbed wire can effectively manage numerous types of animals. Additionally, it can be used in agricultural settings to protect crops and gardens from animal intrusion, ensuring that valuable produce is safeguarded. Cost-Effectiveness Investing in fencing can be a significant expense for farmers and ranchers. However, Cattleman Pro 14G barbed wire offers a cost-effective solution without compromising on quality. Its durability means less frequent replacements, leading to reduced maintenance costs over time. Furthermore, the ease of installation lowers labor costs, making it a financially sensible option for landowners looking to secure their property and livestock effectively. Installation and Maintenance Installing Cattleman Pro 14G barbed wire is a relatively straightforward process. With the right tools and equipment, farmers and ranchers can easily set up their fencing. Moreover, the maintenance requirements for barbed wire are minimal. Periodic inspections for damage and tightening loose sections typically suffice to keep the fence in good condition. This ease of upkeep contributes to the overall appeal of Cattleman Pro wire as a fencing option for farmers. Conclusion In summary, Cattleman Pro 14G barbed wire is a robust, versatile, and cost-effective solution for anyone in need of reliable fencing. Its strength and durability, combined with enhanced security and ease of installation, make it an outstanding choice for livestock management and property security. Whether you are a seasoned rancher or a new landowner, investing in Cattleman Pro barbed wire will not only protect your animals but also provide peace of mind as you manage your assets with confidence. For those looking to enhance their fencing solutions, Cattleman Pro 14G barbed wire is undoubtedly worth considering.

- Galvanized Hexagonal Wire Fencing for Versatile Outdoor Applications and Secure Confinement******Galvanised Hexagonal Wire Netting A Versatile Solution for Various Applications Galvanised hexagonal wire netting, commonly known as chicken wire or hex wire mesh, is a type of fencing material widely used in agriculture, garden, and construction applications. The distinctive hexagonal pattern offers a range of benefits that make it an ideal choice for various projects. Its versatility, durability, and ease of use have made it an essential material in many industries. One of the primary advantages of galvanised hexagonal wire netting is its robust construction. Made from high-quality steel wire that is coated with a layer of zinc, the galvanisation process protects the metal from rust and corrosion. This makes it suitable for outdoor use, where exposure to moisture and weather elements can lead to deterioration. The longevity of galvanised wire mesh means that it frequently outlasts other types of fencing, resulting in lower replacement costs over time. The hexagonal design of the wire netting provides optimal support while allowing for airflow and light penetration, making it an excellent choice for gardening and landscaping. Gardeners often utilize this type of netting to create protective barriers around flowerbeds, vegetable patches, and plants, preventing pests such as rabbits and deer from causing damage. Additionally, the hexagonal shape allows bees and other pollinators to easily navigate through the mesh, promoting a healthy ecosystem. galvanised hexagonal wire netting In agriculture, galvanised hexagonal wire netting is frequently employed in the construction of animal enclosures and coops. It is especially popular for fencing around poultry farms, as it allows easy visibility and airflow while keeping chickens contained and protected from predators . The mesh is available in various wire gauges and mesh sizes, enabling farmers to select the right type that suits their specific needs. This adaptability is one reason why farmers continue to rely on this material for their livestock management. Another application of galvanised hexagonal wire netting is in the construction industry, where it serves as a vital component in various structures. It can be used for reinforcing concrete and as support in plastering. This mesh adds tensile strength to walls and ceilings, ensuring structural integrity and stability. The flexibility of wire netting allows for easy handling and installation, making it a favorite among builders and contractors. Despite its many advantages, there are considerations that users must keep in mind. While galvanised wire netting is resistant to rust, it will eventually wear down, especially in areas with harsh environmental conditions. Regular inspections and maintenance can prolong its life and efficiency. Additionally, care should be taken during installation to avoid cutting or damaging the wire, which could compromise its effectiveness and lead to safety hazards. In conclusion, galvanised hexagonal wire netting is a multifaceted material with a wide array of applications ranging from gardening and livestock management to construction. Its durability, ease of use, and protective qualities make it a practical choice for various projects. As industries continue to evolve, galvanised hexagonal wire netting will remain a reliable and adaptable solution for those seeking effective fencing and support structures. Whether for residential use, agricultural purposes, or commercial construction, this wire mesh stands the test of time as a valuable resource.

- Durable Black Coated Wire Fencing for Enhanced Property Security and Aesthetics******The Versatility and Benefits of Black Coated Wire Fencing In today's world, effective fencing solutions are essential for various applications, from security to aesthetics. One such option that is gaining popularity among homeowners and businesses alike is black coated wire fencing. This type of fencing not only serves practical purposes but also offers a stylish appearance that enhances the landscape. Let's explore the versatility and benefits of black coated wire fencing. What is Black Coated Wire Fencing? At its core, black coated wire fencing consists of steel wires coated with a layer of black vinyl or polymer. This coating provides several advantages, making it a preferred choice for residential, commercial, and agricultural uses. The wire is typically made from high-tensile steel, which ensures strength and durability while maintaining a lightweight quality for easy installation. Aesthetic Appeal One of the standout features of black coated wire fencing is its aesthetic appeal. The sleek black finish blends seamlessly with natural surroundings, making it an attractive choice for gardens, parks, and yards. Unlike traditional galvanized wire fencing, which can be harsh on the eyes, black coated fencing provides a refined look that complements various landscapes. This visual appeal makes it especially suitable for residential areas where homeowners wish to maintain a pleasing view without compromising security. Durability and Longevity Black coated wire fencing is designed to withstand the elements. The vinyl coating provides an added layer of protection against rust, corrosion, and UV damage. This durability ensures that the fence will retain its appearance and functionality for years to come, even in harsh weather conditions. With minimal maintenance required, black coated wire fencing represents a cost-effective solution for long-term fencing needs. Security Features Beyond aesthetics, black coated wire fencing offers significant security benefits. The high-tensile steel used in these fences creates a robust barrier that is difficult to penetrate or damage . This makes it an ideal choice for securing properties, gardens, and livestock. The heavy-duty construction can deter intruders and keep pets safe, providing peace of mind for property owners. black coated wire fencing Versatile Applications The versatility of black coated wire fencing is another reason for its growing popularity. It can be used in various settings, including 1. Residential Properties Homeowners can use it to enclose yards, add privacy, or provide a safe play area for children and pets. 2. Commercial Properties Businesses often require secure, yet appealing, fencing solutions for their premises. Black coated wire fencing provides the necessary security while still looking professional. 3. Agricultural Use Farmers can use this fencing to contain livestock or protect crops. Its durability ensures that it can withstand rough conditions typical of agricultural environments. 4. Parks and Recreational Areas Black coated wire fencing is frequently used in parks to create boundaries without obstructing views, allowing visitors to enjoy the scenery. Installation and Maintenance Installing black coated wire fencing is relatively straightforward, especially for those who opt for professional installation. DIY enthusiasts can also find the necessary materials and guidance to set up this type of fencing on their own. Maintenance is minimal; a quick wash to remove dirt and debris will keep the fence looking good. If any scratches occur, a simple touch-up with additional black coating can restore its appearance. Conclusion Black coated wire fencing is a versatile and aesthetically pleasing option that combines function and style. Its durability, security features, and wide range of applications make it an ideal choice for homeowners, businesses, and farmers alike. By choosing black coated wire fencing, property owners can enjoy the benefits of a strong, long-lasting barrier that enhances their surroundings while protecting their space. In a world where both form and function are essential, black coated wire fencing stands out as a valuable investment.

- hardware cloth 5 ft******Exploring Hardware Cloth A Versatile Solution for Home and Garden When it comes to home improvement and gardening projects, one of the most underrated materials is hardware cloth. This galvanized wire mesh is made from steel and is available in a variety of sizes, including the popular 5 ft option. Its unique characteristics make it an excellent choice for a wide range of applications, from animal enclosures to drainage systems. In this article, we will delve into the versatility and uses of hardware cloth, particularly focusing on the 5 ft variant. What is Hardware Cloth? Hardware cloth is a type of wire mesh that is often used in different construction and landscaping projects. It is constructed from thin steel wires that are woven in a grid-like pattern, providing strength and durability. The mesh is available in various gauges and opening sizes, making it adaptable for various functional needs. The 5 ft width is especially popular, as it provides ample coverage for larger projects while remaining manageable for individual homeowners. Common Uses of 5 ft Hardware Cloth 1. Animal Enclosures One of the most common uses for 5 ft hardware cloth is in the construction of animal enclosures. Whether for chickens, rabbits, or other small animals, this sturdy mesh provides a barrier against predators while allowing ample airflow and visibility. The 5 ft height is particularly useful for keeping animals secure without creating an overly confined space. For those looking to keep their pets safe, constructing a run with hardware cloth can offer peace of mind. 2. Garden Protection Gardeners often face challenges from pests that can wreak havoc on their crops. Using 5 ft hardware cloth, you can create protective barriers around vegetable gardens or flower beds. By surrounding your plants with the mesh, you can keep out rabbits, deer, and other critters while still allowing sunlight and rain to nourish your plants. This cost-effective solution is a humane way to protect your botanical endeavors. hardware cloth 5 ft 3. Compost Bins Constructing a compost bin with hardware cloth allows for proper ventilation and drainage while keeping rodents at bay. The 5 ft height is ideal for creating a larger compost area, giving you enough space to contribute organic waste without worrying about unwanted guests. The mesh structure also promotes aeration, which is crucial for successful composting. 4. Support Structures Hardware cloth can also serve as a support structure for climbing plants. When placed vertically or at an angle, the mesh provides a framework for plants like cucumbers, peas, or beans to grow upon. This not only maximizes garden space but also ensures that your plants receive optimal sunlight and air circulation. 5. Drainage Solutions In situations where water drainage is a concern, hardware cloth can be utilized to create effective barriers in landscaping projects. By laying down a layer of hardware cloth over drainage trenches, you can prevent soil erosion while allowing water to pass through unimpeded. This ensures that water is channeled appropriately, protecting your garden from waterlogging. Installation Tips Installing hardware cloth is a straightforward process that can be done with a few simple tools. Start by measuring the area where you intend to install the mesh, ensuring that your cuts are accurate. Use wire cutters to achieve clean edges and gloves to protect your hands from sharp wires. For fencing or enclosures, installing wooden posts will help secure the hardware cloth in place, providing stability and durability. Conclusion The versatility of 5 ft hardware cloth makes it an invaluable addition to any homeowner's toolkit. Whether for creating secure animal enclosures, protecting gardens, or facilitating drainage, its various applications are limited only by your imagination. By integrating hardware cloth into your projects, you can achieve functional, practical, and sustainable solutions that enhance both your home and garden. As you embark on your next DIY adventure, don’t overlook this indispensable material—it's one that can truly make a difference!

- Exploring the Benefits of Stock Netting in Financial Transactions and Risk Management******Understanding Stock Netting Fence A Comprehensive Overview In the realm of financial management and investment strategies, companies continuously seek methods to optimize their operations, reduce risks, and enhance profitability. One innovative concept that has gained traction in recent years is the idea of a stock netting fence. This strategy seeks to manage and mitigate risks associated with stock fluctuations while maximizing returns. In this article, we will dive into what a stock netting fence is, how it operates, and the benefits it can offer to investors. What is a Stock Netting Fence? At its core, a stock netting fence is a financial mechanism employed to manage exposure to stock price fluctuations. It encompasses strategies that involve offsetting potential losses in one investment with gains in another, effectively creating a 'fence' around stock values to protect against adverse movements. This approach can be particularly beneficial for corporations with diverse portfolios, enabling them to stabilize their overall market presence. How Does It Work? The operation of a stock netting fence involves several critical components . Firstly, the concept is reminiscent of hedging—where investors use financial instruments, like options and futures, to protect against the risk of unfavorable price movements. For instance, an investor who holds a significant position in a volatile stock may choose to buy put options to offset potential declines in that stock's value. If the stock price tumbles, the gains from the put options can compensate for the losses incurred, thereby creating a netting effect. A stock netting fence also involves the strategic selection of diversified investments. By holding a varied portfolio that includes stocks from different sectors, industries, or geographical areas, investors can lessen their overall exposure to any single stock's performance. Stocks tend to move independently, and by carefully selecting these investments, an investor can create a natural netting effect, smoothing out the performance across the portfolio. stock netting fence Benefits of Implementing a Stock Netting Fence The primary benefit of using a stock netting fence is risk reduction. By offsetting potential losses in one area with gains in another, investors can protect their capital against market volatility. This protective measure enhances peace of mind, allowing companies and individual investors to focus on long-term growth rather than short-term fluctuations. Additionally, a stock netting fence can improve capital efficiency. When companies are able to manage their stock risk more effectively, they can allocate resources more optimally, potentially leading to increased profitability. Investors may be more inclined to take calculated risks when they have a solid netting strategy in place, fostering a more dynamic investment approach. Moreover, such strategies can facilitate better financial planning and forecasting. When stocks are netted off against one another, companies can make more accurate predictions about their potential financial outcomes. This reliability can be invaluable for budgeting and capital allocation decisions, ultimately contributing to enhanced operational efficiency. Conclusion In conclusion, the stock netting fence is an innovative strategy that offers numerous advantages to investors and companies alike. By implementing mechanisms to hedge against stock price fluctuations and diversify investments, organizations can protect themselves from unforeseen volatility and maximize their long-term returns. As financial markets continue to evolve, understanding and utilizing such strategies will be crucial for sustaining growth and maintaining a competitive edge. Embracing concepts like the stock netting fence can empower investors to navigate the complexities of the stock market with confidence and strategic insight.

- hexagonal mesh manufacturer******Understanding the Importance of Hexagonal Mesh Manufacturers In the world of manufacturing and construction, the significance of using the right materials cannot be overstated. Among various types of materials, hexagonal mesh is becoming increasingly popular across several industries, owing to its unique properties and versatility. Hexagonal mesh manufacturers play a crucial role in supplying this innovative material, catering to a variety of applications. What is Hexagonal Mesh? Hexagonal mesh, also known as hex mesh, is a type of wire mesh characterized by its hexagonal-shaped openings. It is typically made from steel or other durable materials, making it strong and long-lasting. The unique design of the mesh contributes to its lightweight yet robust characteristics, allowing for efficient use in numerous sectors. Applications of Hexagonal Mesh Hexagonal mesh finds applications in a wide range of industries, including construction, agriculture, and industrial settings. In construction, hexagonal mesh is often used for reinforcement purposes. It can be integrated into concrete structures to enhance tensile strength and provide additional support. This is particularly beneficial in building walls and ceilings as it helps to prevent cracking and structural failures. In agricultural settings, hexagonal mesh is widely used for creating enclosures and fencing. Its design allows for excellent ventilation while also providing adequate security for livestock or crops. Farmers appreciate its durability and resistance to corrosion, which ensures long-lasting performance even in harsh environmental conditions. Choosing the Right Hexagonal Mesh Manufacturer hexagonal mesh manufacturer When searching for a hexagonal mesh manufacturer, several factors need to be taken into consideration to ensure quality and reliability. First, it is crucial to evaluate the manufacturer’s experience and reputation in the industry . Established manufacturers with a proven track record are more likely to provide high-quality products that meet industry standards. Quality control is another vital aspect to examine. Reputable manufacturers implement rigorous quality assurance processes during production to ensure that their hexagonal mesh is free from defects and capable of withstanding the stresses of its intended environment. Certifications such as ISO can also indicate a commitment to maintaining high-quality standards. Furthermore, consider the range of products and customization options available. Some manufacturers specialize in various sizes, thicknesses, and materials for hexagonal mesh, allowing customers to choose according to their specific needs. Customization is particularly beneficial for unique projects that require specific dimensions or properties. Sustainability Considerations In today’s environmentally conscious market, the sustainability practices of a hexagonal mesh manufacturer are increasingly important. More consumers and businesses are opting for manufacturers who prioritize eco-friendly materials and production methods. This includes sourcing raw materials responsibly and minimizing waste throughout the manufacturing process. When partnering with a hexagonal mesh manufacturer, it is essential to inquire about their sustainability practices. This not only reflects a commitment to protecting the environment but also aligns with the growing trend of using sustainable materials in construction and agriculture. Conclusion Hexagonal mesh manufacturers provide essential products that are crucial for various industries. The versatility, strength, and lightweight nature of hexagonal mesh make it an attractive choice for construction, agriculture, and engineering projects. By carefully selecting a reputable manufacturer who adheres to quality standards and sustainable practices, businesses can ensure reliable and effective use of hexagonal mesh in their applications. The continued growth and popularity of hexagonal mesh in the market highlight the importance of these manufacturers in supporting industrial innovation and sustainability efforts. As industries evolve, the demand for quality materials like hexagonal mesh will only increase, making the role of manufacturers more critical than ever.

- Enhancing Protection with Advanced 358 Security Fencing Solutions for Maximum Safety******Understanding 358 Security Fencing The Ultimate Protection Solution In an era where security is of utmost importance, especially for businesses and critical infrastructure, choosing the right fencing can make a significant difference. One product that has gained substantial attention in security circles is the 358 security fence. Often referred to as “prison mesh,” this type of fencing offers robust protection against intrusion and vandalism, making it an ideal choice for institutions like correctional facilities, military bases, airports, and more. What is 358 Security Fencing? The term 358 refers to the dimensions and specifications of the wire mesh used in the fencing. Specifically, the wire gauge is 3mm, the mesh size is 50mm x 200mm, and the height of the fence is typically 2.4 meters, although it can be customized according to specific needs. This design is deliberate— the narrow openings in the mesh prevent handholds and footholds for would-be intruders, thus enhancing security. The thickness of the wire makes it incredibly tough and resistant to bending and breaking. Additionally, 358 security fences are often made from galvanized steel and feature a powder-coated finish, providing enhanced durability and resistance to rust and corrosion. Advantages of 358 Security Fencing 1. High Visibility One of the standout features of 358 security fencing is that it provides high visibility while remaining challenging to scale. The mesh design allows for clear sightlines, which can deter criminal activity as potential intruders feel exposed. 2. Security and Strength The robust materials used in construction mean that 358 fences are designed to withstand various types of physical attacks. They are particularly effective against cutting tools and bolt cutters commonly used in unauthorized entry attempts. 3. Minimal Maintenance Due to the galvanized and powder-coated finishes, these fences require minimal maintenance. They are designed to endure harsh weather conditions, which means they will maintain their integrity and appearance over time without constant repairs or replacements. 358 security fence 4. Cost-Effective Security While the initial installation cost might be higher than that of traditional fencing options, the long-term savings in maintenance and potential losses from theft or vandalism often make 358 fences a more cost-effective security solution. 5. Adaptability 358 security fencing can be easily adapted to fit different sites and requirements. It can be added with various security features, such as barbed wire on top, anti-climb toppings, or integrated security systems for comprehensive protection. 6. Environmental Considerations Many manufacturers of 358 security fencing are now focusing on environmentally-friendly practices. The materials used can often be recycled, and the production processes are being designed to minimize carbon footprints. Applications of 358 Security Fencing The versatility of 358 security fencing makes it suitable for a wide range of applications. Commonly found in - Prisons and Correctional Facilities Its design effectively prevents escapes while keeping the facility secure from external threats. - Airports and Military Bases High-security environments benefit greatly from the visibility and resistance offered by this type of fencing. - Public Utilities and Power Stations Protecting critical infrastructure from vandalism and theft is vital, and 358 fencing serves this purpose effectively. - Commercial Properties Businesses looking to secure their premises from trespassers and theft find 358 fencing both effective and reassuring. Conclusion In conclusion, 358 security fencing stands out as a leading solution in the realm of high-security fencing. Its unique design features, combined with its durability and effectiveness, make it a preferred choice for a myriad of applications. As security concerns continue to grow in modern society, investing in solutions like the 358 security fence can ensure that businesses and institutions remain protected against potential threats. Its ability to provide a clear, strong barrier without sacrificing visibility is what ultimately sets it apart as one of the most reliable choices in security fencing today.

- Explore Top Manufacturers of Razor Barbed Wire Fencing for Your Security Needs******Understanding the Purchase of Razor Barbed Wire Fences A Comprehensive Guide When it comes to securing property, whether for agricultural, industrial, or residential purposes, one of the most effective options available is the razor barbed wire fence. Its formidable design and durable construction make it a popular choice for a variety of applications. This article delves into the intricacies of purchasing razor barbed wire fence products from factories, outlining what you need to know for making an informed decision. What is Razor Barbed Wire? Razor barbed wire consists of strong wire strands intertwined with sharp barbs at regular intervals. These barbs can deter trespassers and animals, making it a preferred security solution for sensitive areas. The wire is often galvanized to resist corrosion, ensuring longevity. Its intimidating appearance acts as a psychological barrier, thus enhancing the overall security of the premises. Why Buy from Factories? Purchasing directly from factories offers several advantages. First and foremost, it often ensures lower costs. By eliminating intermediaries such as wholesalers and retailers, buyers can benefit from wholesale prices. Additionally, purchasing from manufacturers allows for greater customization. Buyers can specify the gauge of the wire, barbed spacing, and even the type of coating. Factors to Consider When Buying Razor Barbed Wire 1. Material Quality Ensure that the wire is made from high-quality steel and is corrosion-resistant. Hot-dip galvanization is preferred as it provides a thicker zinc coating, enhancing durability. 2. Gauge Size The gauge of the wire (the thickness) is crucial. A lower gauge indicates a thicker wire, which is generally more durable and harder to cut. Depending on your security needs, you may choose from various gauges. 3. Barb Configuration Barbed wire comes in different configurations, such as single barbs or double barbs. Consider your security needs and the level of deterrence required when choosing the barb configuration. 4. Length and Roll Size Razor barbed wire is typically sold in rolls. Determine how much fencing you need and choose the appropriate roll sizes . Some factories offer custom roll lengths, which can be beneficial for larger projects. buy razor barbed wire fence factories 5. Manufacturing Standards Check if the factory adheres to international quality standards, which ensures that the fence products meet safety and durability requirements. Certifications such as ISO can be indicators of quality. Searching for Factories 1. Online Directories Utilize online industrial directories and trade platforms to find reputable razor barbed wire factories. Websites like Alibaba, Global Sources, and Made-in-China are excellent starting points to compare different manufacturers. 2. Trade Shows Attending trade shows related to security solutions or construction materials can provide an opportunity to meet manufacturers, inspect their products, and establish direct business relationships. 3. Reviews and Testimonials Research reviews and testimonials from previous customers to gauge the reliability and quality of the products offered by a particular factory. 4. Requesting Samples Before making a bulk purchase, request samples to assess the product quality firsthand. This step is crucial as it helps you verify that the product meets your expectations. Making the Purchase Once you’ve chosen a factory, it's essential to finalize your order with clear specifications regarding materials, dimensions, quantities, and delivery timelines. Always inquire about payment terms and warranty policies. A reliable manufacturer should offer some guarantee of their products' performance. Conclusion Investing in razor barbed wire fencing is a proactive step towards securing your property. By buying directly from factories, you not only save costs but can also enjoy customized solutions that fit your specific needs. With careful consideration of material quality, gauge size, and manufacturing standards, you can find a solution that offers robust security for years to come. Take the time to research and connect with reputable manufacturers, ensuring that you make a wise investment in your property’s safety.

- Durable White Farm Fence with Wire Mesh - Enhance Your Property's Security******The Advantages of White Farm Fences with Wire Mesh In the world of agriculture, fencing plays a crucial role in maintaining the safety and integrity of livestock, crops, and property. Among the various options available, white farm fences combined with wire mesh have emerged as a popular choice for many farmers and property owners. These fences not only enhance the aesthetic appeal of a farm but also offer numerous practical benefits. One of the primary advantages of white farm fences is their visibility. The stark contrast of white against green pastures ensures that both livestock and visitors can easily see the boundaries of a property. This visibility is essential for preventing animals from straying and for establishing clear property lines. When combined with wire mesh, these fences create a formidable barrier that keeps livestock safely contained while deterring unwanted intruders. Another significant benefit of a white farm fence with wire mesh is its durability. Made typically from high-quality materials, these fences are designed to withstand various weather conditions, from heavy rains to intense sunlight . The wire mesh adds an extra layer of strength, making the fence more resistant to wear and tear over time. This durability translates to lower maintenance costs, as farmers won't have to frequently replace or repair their fencing. white farm fence with wire mesh Aesthetic appeal is another compelling reason to choose white farm fences. The clean and classic look of white-painted wood or vinyl fencing can enhance the beauty of any agricultural landscape. It creates a welcoming atmosphere and can increase the overall value of the property. Potential buyers are often drawn to well-maintained farms that showcase attractive fencing. Moreover, these fences are versatile and can be customized to meet specific needs. Whether it’s enclosing a large pasture or creating smaller paddocks, white farm fences with wire mesh can be tailored to different sizes and shapes. This adaptability makes them suitable for various types of farms, whether for cattle, horses, or crops. In addition to functionality and beauty, white farm fences are easier to maintain than traditional wooden fences. The smooth surface of vinyl or treated wood simplifies cleaning and reduces the likelihood of splinters, making it safer for both animals and humans. A simple wash with a hose can keep the fence looking fresh and new. Ultimately, white farm fences with wire mesh represent a perfect blend of style, durability, and functionality. They provide an excellent solution for farmers looking to protect their land and livestock while enhancing the visual appeal of their property. With this combination, property owners can ensure their farms are as effective as they are beautiful.

- Electric Fencing Solutions for Protecting Chickens and Livestock Efficiently and Safely******The Versatility of Electric Chicken Fence Netting In modern poultry farming, ensuring the safety and protection of chickens is paramount. One of the most effective solutions for keeping chickens safe from predators while allowing them the freedom to roam is the use of electric chicken fence netting. This innovative fencing option not only serves as a physical barrier but also incorporates electrical elements to deter both wildlife intrusions and unwanted pests. Electric chicken fence netting consists of lightweight, durable materials designed specifically for poultry. Its mesh structure allows for adequate ventilation and visibility for the birds while maintaining a secure enclosure. The electric components of the netting deliver a mild shock to any animal that attempts to breach the fence, teaching them to stay away without causing serious harm. This method of animal husbandry not only protects the chickens but also promotes a more humane approach to managing wildlife interactions. One of the primary benefits of electric chicken fence netting is its portability. Unlike traditional fencing solutions, which can be costly and time-consuming to install, electric netting can be easily moved to different locations. This is especially advantageous for those who practice rotational grazing, as hens can be directed to fresh pastures without compromising their security. By rotating the location of the fenced area, farmers can enhance their chickens' diet with diverse forage and minimize overgrazing in any one spot. In addition to being portable, electric chicken fence netting is also straightforward to set up. Many products come with user-friendly manuals, and the materials required for installation are typically minimal . Most electric fences can be set up within a few hours, making them an attractive option for both novice and experienced poultry farmers alike. The flexibility in installation options also means that farmers can configure their fencing to match varying terrains and space requirements. electric chicken fence netting Moreover, electric chicken fence netting is designed to be resilient. Constructed from high-quality materials, it can withstand different weather conditions, from harsh sun exposure to heavy rains. This durability ensures long-term effectiveness, allowing farmers to invest in a solution that will protect their flocks for years to come. Safety features also add to the appeal of electric chicken fence netting. Each fence is equipped with grounding rods and proper insulation to minimize risks associated with electricity. Additionally, the shock delivered is designed to be uncomfortable and discouraging, significantly reducing the chance of fatal injuries to both the intruding animals and the farm's poultry. In terms of cost, while there is an initial investment for electric chicken fence netting, the long-term savings speak volumes. By effectively keeping predators at bay, farmers reduce the risk of losing their investments in chickens. With the average cost of raising chickens increasing due to feed and care expenses, effective predator management is crucial for maintaining profitability in poultry farming. In conclusion, electric chicken fence netting offers a versatile, effective, and humane solution for protecting chickens from predators while allowing them the freedom to roam. Its portability, ease of installation, durability, and safety features make it a popular choice among poultry farmers. As the demand for humane animal husbandry practices continues to grow, adopting such innovative solutions paves the way for a more sustainable and ethical approach to farming. Whether for backyard enthusiasts or larger commercial operations, electric chicken fence netting provides an essential tool for successful poultry farming.

- Guide to Installing Razor Wire Effectively and Safely for Enhanced Security******Razor Wire Installation Ensuring Security with Precision and Care Razor wire, known for its sharp edges and formidable appearance, has been widely used in security fencing and barriers. Its installation is a crucial process that requires careful planning, precision, and adherence to safety standards. This article explores the essential aspects of razor wire installation, including its benefits, methods, and best practices. Benefits of Razor Wire Razor wire provides a high level of deterrence against trespassers and intruders. Its design, featuring sharp barbs, makes it nearly impossible to climb without injury, thus serving as an effective physical barrier. This security solution is commonly found in prisons, military bases, industrial facilities, and other high-security locations. Beyond its formidable appearance, razor wire is also cost-effective when compared to other security measures such as surveillance systems and hired security personnel. Planning for Installation Before installing razor wire, it is vital to conduct a thorough assessment of the site. This includes considering the terrain, the types of security threats that might be present, and the legal regulations governing the use of such deterrents in your area. It is also essential to determine the appropriate height and design of the installation. Proper planning will not only enhance security but also ensure that the installation complies with local laws and safety standards. Tools and Materials Required The installation of razor wire requires specific tools and materials. Essential tools include - Safety Equipment Gloves, goggles, and hard hats to protect workers from injuries. - Fencing Tools Wire cutters, pliers, and fencing staples for securing the wire to the fence. - Support Structures This may include existing fences, poles, or other types of barriers to which the razor wire will be attached. The razor wire itself should be of high quality, meeting safety and durability standards to ensure effectiveness in harsh weather conditions . razor wire installation Steps for Installation 1. Preparation Clear the installation site to ensure there is no debris or obstruction. This will make the installation process smoother. 2. Measuring and Marking Measure the section of the fence where the razor wire will be installed. Use paint or markers to indicate where the wire will be attached. 3. Attaching the Razor Wire Begin by unrolling the razor wire carefully. Using fencing staples or wire ties, attach the razor wire to the fence at regular intervals. It is crucial to ensure that the wire remains taut to prevent sagging, which could make it easier for intruders to access. 4. Creating Loops For added security, consider looping the razor wire to create a barrier that is not only difficult to climb over but also poses a significant risk to anyone attempting to breach it. 5. Final Checks After installation, conduct a thorough inspection of the razor wire to ensure that all sections are secure and that there are no sharp ends exposed that might pose a risk to animals or people nearby. Maintenance of Razor Wire After installation, ongoing maintenance is necessary to ensure the razor wire remains effective. Regular inspections should be conducted to check for signs of wear, rust, or damage caused by environmental factors. Additionally, vegetation should be kept clear around the perimeter to maintain visibility and deterrence. Conclusion Razor wire installation is an effective method for enhancing security in vulnerable areas. With proper planning, tools, and adherence to safety standards, it can serve as a highly reliable barrier against intrusion. By following the best practices outlined in this article, individuals and organizations can ensure their razor wire installations provide the maximum level of security and protection.