Wholesale Roofing Nails for All Your Construction Needs and Projects******The Essentials of Wholesale Roofing Nails A Comprehensive Guide When it comes to roofing projects, the importance of high-quality materials cannot be overstated. Among these materials, roofing nails play a pivotal role in ensuring that roofs are securely attached and weather-resistant. For contractors and builders looking to manage costs while maintaining quality, buying roofing nails wholesale is an attractive option. This article aims to provide a comprehensive overview of wholesale roofing nails and the advantages of purchasing them in bulk. Understanding Roofing Nails Roofing nails are specialized fasteners designed to hold roofing materials in place, such as shingles, tiles, or metal sheets. They typically have a wide, flat head to offer a greater surface area and reduce the risk of tearing the roofing material. Roofing nails come in various lengths and gauges, and the choice largely depends on the type of roofing material being used. For example, longer nails are required for thicker materials, while shorter nails suffice for thinner ones. Types of Roofing Nails When purchasing roofing nails wholesale, it's essential to understand the different types available 1. Galvanized Roofing Nails These nails are coated with zinc to prevent rust and corrosion, making them ideal for areas with high moisture levels. Their longevity and durability make them a popular choice among contractors. 2. Stainless Steel Roofing Nails A more expensive option, stainless steel nails offer superior resistance to rust and corrosion. They are particularly suited for harsh environments and are often used for coastal roofing projects where saltwater can accelerate corrosion. 3. Plastic Cap Roofing Nails These nails feature a plastic cap that helps to hold down roofing materials while also offering increased resistance against water infiltration. They are often used for roofing underlayment and other waterproofing projects. 4. Coil Roofing Nails These are specially designed for use with pneumatic nail guns. Coil nails are efficient for large projects, allowing for quick application, significantly speeding up the roofing process. Benefits of Buying Roofing Nails Wholesale wholesale roofing nails 1. Cost-Effectiveness One of the primary benefits of purchasing roofing nails wholesale is the significant cost savings. Buying in bulk usually comes with a discounted price, allowing contractors to reduce their project budgets without sacrificing quality. 2. Convenience By sourcing all your roofing materials, including nails, from a wholesale supplier, you can streamline your purchasing process . This reduces the time spent searching for different suppliers and helps to ensure consistency in quality. 3. Variety and Availability Wholesale suppliers often have a larger inventory of roofing nails compared to retail stores, which means you can find a wider variety of types and sizes. This variety can be crucial when working on diverse projects that require specific materials. 4. Long-Term Relationships Establishing a relationship with a wholesale supplier can lead to better deals and preferential treatment in the long run. As suppliers come to understand your needs and preferences, they may offer tailored solutions and discounts for future purchases. Considerations When Purchasing Wholesale Roofing Nails While wholesale purchases offer numerous benefits, there are a few considerations to keep in mind - Quality Assurance Always ensure that the nails meet industry standards. Inferior quality can lead to issues such as rust, breakage, or failure to hold roofing materials securely. - Storage and Handling Bulk purchases require appropriate storage. Ensure that you have the capacity to store the nails properly to prevent damage or degradation. - Supplier Reputation Research and select reputable wholesale suppliers who have positive reviews and reliable customer service. Conclusion Roofing nails may seem like a small detail in the grand scheme of a roofing project, but they are integral to the integrity and durability of the roof itself. Opting for wholesale roofing nails can save money, provide convenience, and ensure you have access to a wide array of products. By understanding the types of nails available and the benefits of purchasing in bulk, contractors and builders can improve their efficiency and the overall quality of their roofing projects. Investing in high-quality roofing nails is an investment in the longevity of every roofing job, supporting both the structure and the peace of mind of those who rely on it._bulk chicken wire fencing

Exploring Sustainable Solutions with Green Wire Netting for Eco-Friendly Projects

Understanding Green Wire Netting and Its Applications Wire netting, commonly referred to as wire mes...

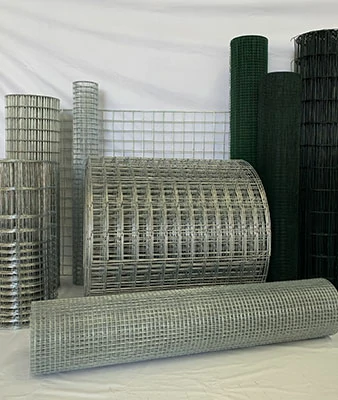

Wholesale Welded Wire Mesh Panel Manufacturers and Suppliers in the Market

Wholesale Welded Mesh Panel Factories An Overview of the Industry In the ever-evolving world of cons...

Durable PVC Coated Barbed Wire for Enhanced Security and Longevity in Fencing Solutions

Understanding PVC Barbed Wire An Overview In the realm of fencing solutions, security is a paramount...

electric wire netting

The Versatility and Applications of Electric Wire Netting Electric wire netting, commonly referred t...

緑の鉄条網フェンス価格。

グリーンチェーンリンクフェンスの価格について 近年、プライバシーやセキュリティを重視する家庭や企業が増えてきています。その中で、多くの人々が選択するのがグリーンチェーンリンクフェンスです。今回は、グリ...

Green Wire Fencing for Secure and Stylish Garden Boundaries

wire fence green ....

حصار سياه سياه سياه

مشخصات و مزایای نردههای مش سیمی سیاه نردههای مش سیمی سیاه یکی از گزینههای محبوب برای محافظت از من...

fencing wire mesh price

Understanding Fencing Wire Mesh Prices A Comprehensive Guide When it comes to creating secure bounda...

सायनी लिंक फेन्स वायर

चेन लिंक फेंस वायर सुरक्षा आणि सौंदर्याची एकत्रितता चेन लिंक फेंस वायर हे एक अत्यंत उपयुक्त आणि लोकप...

Links

- Innovative Designs Using Single Barbed Wire for Enhanced Security and Aesthetics******The Significance and Utility of Single Barbed Wire Barbed wire has long been an integral component in the architecture of fencing, serving multiple purposes ranging from security to livestock management. Among the various types of barbed wire, single barbed wire stands out for its simplicity, effectiveness, and versatility. This article explores the characteristics, applications, and advantages of single barbed wire, illustrating why it remains a relevant choice in modern fencing solutions. Characteristics of Single Barbed Wire Single barbed wire consists of a single strand of wire with uniformly spaced barbs that protrude at intervals along the length. Typically made from durable materials such as galvanized steel or high-tensile wire, single barbed wire possesses characteristics that make it both robust and resistant to environmental wear. The barbs, sharp and pointed, are designed to deter animals and intruders while allowing the wire to maintain flexibility, which is essential for easy installation and adaptability to various types of terrain. Applications of Single Barbed Wire 1. Agricultural Fencing One of the primary uses of single barbed wire is in agricultural settings. It is commonly employed to enclose pastures or grazing areas. The presence of barbs prevents livestock from wandering off and helps keep wild animals at bay, ensuring the safety and productivity of farming operations. 2. Security Fencing Single barbed wire is also widely used in security installations, such as around industrial sites, military bases, and correctional facilities. Its intimidating appearance naturally discourages trespassing, while the physical barrier it creates adds an essential layer of protection to sensitive areas. 3. Boundary Marking Beyond its protective capabilities, single barbed wire serves as an effective means of clearly marking property lines. In rural and suburban environments, barbed wire fences often delineate ownership and prevent disputes between neighboring landowners . single barbed wire 4. Wildlife Control In regions where wildlife poses a risk to crops or livestock, single barbed wire can act as a barrier to keep wild animals out. This application is particularly important in areas where feral animals may disrupt farming activities or pose threats to livestock. Advantages of Single Barbed Wire One of the major advantages of single barbed wire is its cost-effectiveness. Compared to other fencing solutions, such as wood or vinyl, single barbed wire is relatively inexpensive to purchase and install. This makes it an attractive option for individuals or businesses operating on a budget. Additionally, single barbed wire requires minimal maintenance. Unlike wooden fences that may rot or require repainting, barbed wire maintains its integrity in various weather conditions. Galvanization further enhances its lifespan by preventing rust and corrosion, ensuring that the investment lasts for many years. Furthermore, the ease of installation makes single barbed wire a preferred choice for many users. Fencing can be erected quickly with minimal labor, allowing property owners to secure their land efficiently. The wire’s flexibility also means it can be easily adapted to the contours of the land, making it suitable for a wide range of environments. Conclusion In conclusion, single barbed wire is a highly functional fencing option that balances effectiveness, affordability, and ease of use. Its various applications—from securing agricultural lands to protecting industrial sites—underscore its versatility as a fencing solution. Despite the emergence of alternative fencing methods, single barbed wire continues to hold its own due to its ease of installation, low maintenance costs, and durability. For property owners seeking a reliable way to demarcate boundaries or secure premises, single barbed wire remains a go-to option, rooted in both tradition and practicality. Whether for agricultural, security, or boundary-marking purposes, single barbed wire proves that sometimes, simplicity is the key to lasting effectiveness in the world of fencing.

- Rostvrij stalen prikkeldraad voor beveiliging en omheining van terreinen en tuinen******RVS Prikkeldraad Duurzaamheid en Toepassingen RVS prikkeldraad, oftewel roestvrijstalen prikkeldraad, is een essentieel onderdeel in de wereld van omheining en beveiliging. Dit type prikkeldraad onderscheidt zich niet alleen door zijn functionaliteit, maar ook door zijn duurzaamheid en lange levensduur. In deze artikel zullen we de voordelen van RVS prikkeldraad verkennen en enkele van de belangrijkste toepassingen ervan bespreken. Wat is RVS Prikkeldraad? RVS prikkeldraad is vervaardigd uit hoogwaardig roestvrij staal, wat zorgt voor uitstekende weerstand tegen corrosie en oxidatie. Dit maakt het materiaal uitermate geschikt voor gebruik in diverse omgevingen, waaronder gebieden met extreme weersomstandigheden of een hoge luchtvochtigheid. In tegenstelling tot traditioneel prikkeldraad, dat vaak van verzinkt staal is gemaakt, behoudt RVS prikkeldraad zijn sterkte en uitstraling, zelfs na jaren van blootstelling aan de elementen. Voordelen van RVS Prikkeldraad 1. Duurzaamheid Een van de grootste voordelen van RVS prikkeldraad is de duurzaamheid. Het materiaal heeft een veel langere levensduur dan verzinkt staal en vereist minder onderhoud. Dit maakt het een kosteneffectieve keuze op de lange termijn. 2. Corrosiebestendigheid RVS prikkeldraad is uitermate bestand tegen roest en corrosie. Dit is vooral belangrijk in kustgebieden of landschappen met een hoge luchtvochtigheid, waar andere materialen snel kunnen verslechteren. 3. Esthetiek RVS heeft een moderne, glanzende uitstraling die in veel omgevingen esthetisch aantrekkelijk is. Dit maakt het een uitstekende keuze voor residentiële en commerciële toepassingen waar uiterlijk een rol speelt. 4. Veiligheid Prikkeldraad als zodanig biedt een effectieve barrière tegen ongewenste indringers. RVS prikkeldraad is moeilijk te doorbreken, wat de veiligheid van onroerend goed vergroot. stainless barbed wire Toepassingen van RVS Prikkeldraad RVS prikkeldraad wordt in diverse sectoren en toepassingen gebruikt - Landbouw Boeren gebruiken prikkeldraad om hun eigendommen te omheinen en om dieren in bepaalde gebieden te houden. De duurzaamheid van RVS is een groot voordeel in de landbouw, waar het prikkeldraad blootgesteld wordt aan allerlei weersomstandigheden. - Commerciële en industriële beveiliging Bedrijven en fabrieken maken vaak gebruik van RVS prikkeldraad om hun terreinen te beveiligen. Het biedt een zichtbare deterrent voor potentiële indringers. - Residentiële toepassingen Huiseigenaren kiezen steeds vaker voor RVS prikkeldraad voor hun tuinen en eigendommen. Het kan dienen als een stijlvolle en veilige omheining die jarenlang meegaat. - Tuinen en landschapsarchitectuur RVS prikkeldraad kan ook worden gebruikt in tuinen als decoratief element, waarbij het een modern tintje toevoegt aan landschapsontwerpen. Conclusie RVS prikkeldraad biedt een reeks voordelen die het tot een populaire keuze maken voor zowel commerciële als particuliere toepassingen. Van zijn ongeëvenaarde duurzaamheid en corrosiebestendigheid tot zijn esthetische aantrekkingskracht, het is een materiaal dat niet alleen functioneel is, maar ook een waardevolle aanvulling kan zijn op elke omgeving. In een wereld waar veiligheid en kwaliteit steeds belangrijker worden, is RVS prikkeldraad een slimme investeringskeuze.

- metal mesh******The Versatility and Applications of Metal Mesh Metal mesh has emerged as one of the most versatile materials in various industries, ranging from construction to electronics and fashion. Characterized by its web-like structure formed by intertwining wires, metal mesh comes in different materials such as stainless steel, aluminum, and copper, each offering unique properties suitable for specific applications. Its outstanding strength, durability, and resistance to corrosion make it an ideal choice in environments where traditional materials may fail. In the construction industry, metal mesh is widely used for reinforcing concrete structures. By incorporating metal mesh into concrete, builders can enhance the tensile strength of slabs and pre-cast elements, contributing to the longevity and stability of buildings. Additionally, metal meshes serve as effective barriers in construction sites, protecting workers and preventing debris from causing accidents. In the realm of filtration, metal mesh plays a crucial role . Due to its ability to allow air or liquid to pass while blocking larger particles, it is commonly used in various filtration systems. From industrial applications, such as water and oil filtration, to household appliances like coffee makers and vacuum cleaners, metal mesh ensures optimal performance and longevity. metal mesh The automotive and aerospace industries have also embraced metal mesh for its lightweight yet strong characteristics. It is utilized in components that require both durability and weight efficiency. Moreover, metal mesh is essential in developing heat exchangers and radiators, where effective heat dissipation is critical for engine performance. Fashion and design industries have not overlooked the potential of metal mesh. Designers utilize it to create unique, eye-catching garments and accessories, leveraging its lightweight properties and ability to be shaped into various forms. The dramatic aesthetics it offers are becoming increasingly popular on fashion runways and in high-end boutiques. From architectural facades to security screens, the applications of metal mesh continue to expand. Its ability to combine functionality with aesthetic appeal makes it a favorite among architects and designers. Innovations in manufacturing processes have also led to advancements in metal mesh products, allowing for more intricate designs and improved performance characteristics. In conclusion, metal mesh is a remarkable material that demonstrates adaptability across multiple industries. Its unique combination of strength, durability, and aesthetic versatility makes it an essential component in modern applications. As technology evolves, we can expect even more innovative uses for metal mesh, solidifying its place as a valuable resource in both industrial and creative endeavors.

- Manufacture of hexagonal wire netting for agricultural and industrial applications******Hexagonal wire netting, also known as chicken wire, is a versatile and widely used type of fencing that is commonly found in farms, gardens, and construction sites. As the name suggests, hexagonal wire netting is made up of hexagonally shaped mesh wire that is woven together to create a strong and flexible barrier. In this article, we will explore the benefits of hexagonal wire netting and why it is important to choose a reputable hexagonal wire netting factory for all your fencing needs. One of the main advantages of hexagonal wire netting is its versatility. It can be used for a variety of purposes, including fencing off livestock, protecting crops from pests, and securing construction sites. The strength and durability of hexagonal wire netting make it ideal for outdoor use, as it can withstand harsh weather conditions and the wear and tear of everyday use. In addition to its versatility, hexagonal wire netting is also easy to install and maintain. Unlike traditional fencing materials such as wood or metal, hexagonal wire netting is lightweight and easy to handle, making it a popular choice for DIY enthusiasts and professionals alike. Its flexible design allows it to be easily shaped and molded to fit any space, making it an excellent choice for irregularly shaped areas. When choosing a hexagonal wire netting factory, it is important to consider the quality of the materials used and the manufacturing process When choosing a hexagonal wire netting factory, it is important to consider the quality of the materials used and the manufacturing process When choosing a hexagonal wire netting factory, it is important to consider the quality of the materials used and the manufacturing process When choosing a hexagonal wire netting factory, it is important to consider the quality of the materials used and the manufacturing process hexagonal wire netting factory . A reputable factory will use high-quality wire that is coated with a protective layer to prevent rust and corrosion. They will also use advanced weaving techniques to ensure that the mesh is strong and durable, with no weak points or gaps. Another important factor to consider when choosing a hexagonal wire netting factory is the level of customer service and support they provide. A good factory will have knowledgeable staff who can help you choose the right type and size of hexagonal wire netting for your specific needs. They will also offer installation advice and guidance on how to maintain your fencing to ensure it lasts for years to come. In conclusion, hexagonal wire netting is a versatile and durable fencing solution that is perfect for a wide range of applications. By choosing a reputable hexagonal wire netting factory, you can ensure that you are getting a high-quality product that will meet your needs and stand the test of time. Whether you are fencing off a garden, protecting your crops, or securing a construction site, hexagonal wire netting is an excellent choice that will provide years of reliable service.

- Understanding the Corrosion Resistance of Iron Nails in Various Environments******The Fascinating World of Iron Nails A Closer Look Iron nails are small yet remarkable objects that play an essential role in our daily lives. These simple metal fasteners have been used for centuries and have a rich history that showcases their importance in construction, craftsmanship, and even art. In this article, we will dive into the fascinating world of iron nails, exploring their history, production, and versatile applications. Historically, the use of nails can be traced back to ancient civilizations. Archaeological evidence indicates that the Egyptians utilized metal fasteners to build their monumental structures over 3,000 years ago. Iron nails, in particular, became prominent in Europe during the Middle Ages when they were hand-forged by blacksmiths. This craftsmanship was a crucial skill, as nails were essential for constructing homes, ships, and furniture. The transition from handmade to machine-made nails in the 19th century revolutionized the industry. Innovations such as the nail-making machine allowed for mass production, making nails more affordable and accessible to the general public. The production of iron nails involves a fascinating process. Initially, iron ore is mined and then subjected to a series of processes to produce wrought iron, which is known for its malleability and ductility. The wrought iron is heated and then formed into shapes, including the familiar nail profile. Once shaped, nails undergo a cooling process, which helps to enhance their strength. Today, modern manufacturing techniques have further improved the quality and efficiency of nail production, allowing for a wide variety of nails to be produced for different applications. iron nails Iron nails are not just practical items; their versatility allows them to be used in a myriad of applications. In construction, iron nails are essential for joining wood materials and creating structures that can withstand various forces. They are commonly used in framing, roofing, and flooring . Additionally, the automotive and manufacturing industries utilize iron nails in assembling various products. Beyond construction, iron nails have also found their way into artistic endeavors. Artists and craftsmen use nails to create intricate sculptures, furniture, and decorative items, showcasing their aesthetic appeal. One important aspect of iron nails is their durability. Iron, when exposed to moisture, tends to rust, which can lead to structural failure over time. To combat this issue, galvanization—a process of coating the iron with zinc—is commonly employed. Galvanized nails are not only corrosion-resistant but also maintain their strength, making them ideal for outdoor applications such as fencing and decking. This protective measure ensures that iron nails can maintain their integrity even in challenging environmental conditions. Besides their practical uses, iron nails also hold cultural significance. In some cultures, nails symbolize strength and stability, often being incorporated into rituals and traditional practices. The act of hammering a nail can be seen as a metaphor for commitment and perseverance, representing the idea of constructing something worthwhile despite obstacles. In conclusion, iron nails, though small, are a cornerstone of human innovation and craftsmanship. From their ancient origins to modern manufacturing techniques, these fasteners have shaped our world in more ways than we can imagine. As we continue to rely on iron nails in construction, art, and industry, it’s essential to recognize their significance and the craftsmanship that goes into every single piece. Whether used to build a sturdy home or create a work of art, iron nails remain an enduring symbol of strength and utility in our everyday lives.

- Nails for Securing Particle Board Efficiently and Effectively in Construction Projects******Nails for Particle Board Selection, Types, and Best Practices When working with particle board, a commonly used engineered wood product, the choice of fastening materials is crucial for achieving a durable and aesthetic finish. Nails, screws, and other fasteners play a significant role in the strength and longevity of the finished products, whether they are furniture, cabinetry, or decorative elements. Among these fastening options, nails remain a popular choice due to their ease of use and efficiency in assembly. Understanding Particle Board Particle board is made from wood chips, sawmill shavings, and wood shavings bonded together with a synthetic resin or binder. The board is typically less expensive than solid wood or plywood, making it a popular choice for budget-friendly applications. However, one of the challenges present in particle board is its tendency to split or chip if inappropriate fasteners are used. This highlights the importance of selecting the right type of nails for effective connections. Types of Nails for Particle Board 1. Brads These are thin, short nails that are excellent for lighter applications such as trim work and securing thin veneers. Given their minimal size, brads create less stress on the material, reducing the risk of splitting. 2. Finishing Nails Slightly larger than brads, finishing nails are commonly used for constructing furniture where a flush finish is desirable . They can be easily driven into the particle board without causing significant damage or splitting. 3. Spike Nails These nails have a larger diameter and are often used for more heavy-duty applications. They provide excellent holding power but may require pre-drilling to prevent splitting, especially in thinner particle board. nails for particle board 4. Galvanized Nails For projects that may encounter moisture, galvanized nails offer resistance to rust and corrosion. This is especially important for any particle board exposed to humidity, such as in kitchen or bathroom installations. Best Practices for Using Nails with Particle Board - Pre-drilling For thicker boards or harder woods, pre-drilling can prevent the particle board from splitting. This is especially true when using spike nails or heavier fasteners. The drill hole should be slightly smaller than the nail diameter to ensure a snug fit. - Spacing and Placement It is essential to plan the spacing of nails carefully. Placing nails too close together can weaken the panel, while dwelling too far apart may reduce the overall strength of the joint. A general rule of thumb is to place nails no closer than 3 inches apart. - Choosing Appropriate Length The length of the nails selected should be proportional to the thickness of the particle board. A rule of thumb is to use nails that are 1.5 times the thickness of the board for adequate holding power. - Angle Driving For connections that require additional strength, consider driving the nails at an angle. This technique, known as 'toenailing', can enhance the structural integrity of joints. Conclusion Using nails to assemble particle board products can contribute significantly to the overall success of a project, but it requires an informed approach. Understanding the types of nails available, along with best practices for their use, can maximize the durability and aesthetics of finished items. Whether you opt for brads, finishing nails, or spike nails, the goal is to create a strong bond while minimizing damage to the particle board. With careful selection and application, your project can achieve both practical functionality and a polished appearance.

- razor mesh fence******The Versatility and Benefits of Razor Mesh Fencing In the world of security and boundary protection, razor mesh fencing stands out as a formidable choice. This type of fencing is designed to deter intruders and enhance safety for various properties, including residential, commercial, and industrial sites. With its unique characteristics and numerous advantages, razor mesh fencing has become increasingly popular among property owners seeking secure solutions. What is Razor Mesh Fencing? Razor mesh fencing is constructed from high-tensile steel wire that is processed into a zigzag pattern to create sharp, protruding edges. This design is not only effective in preventing unauthorized access, but it also serves as a visual deterrent. The sharp edges make it extremely difficult for potential intruders to climb over, thus enhancing the security of the premises. Additionally, the materials used in razor mesh fencing are typically galvanized or coated, providing resistance against corrosion and prolonging the lifespan of the fence. Key Benefits of Razor Mesh Fencing 1. Enhanced Security The foremost advantage of razor mesh fencing is its ability to provide superior security. The sharp blades deter would-be intruders, creating a significant barrier. This is particularly important for high-risk areas such as prisons, military installations, and high-value commercial properties. 2. Durability Razor mesh fencing is built to withstand harsh weather conditions, making it a robust choice for various climates. The galvanized steel prevents rust and corrosion, ensuring that the fence remains intact and effective for years. razor mesh fence 3. Visibility Unlike solid walls or opaque fences, razor mesh fencing offers high visibility, allowing property owners to monitor their premises easily. This transparency can be beneficial in surveillance and helps to maintain a level of openness while still providing security. 4. Cost-Effectiveness While the initial investment in razor mesh fencing might seem higher compared to traditional fencing options, its durability often translates into lower long-term costs. Property owners save on maintenance and replacement expenses, making it a financially sound choice. 5. Versatility Razor mesh fencing can be adapted to fit various property sizes and configurations. It is available in different heights and can be combined with additional security measures such as alarms and cameras to create a comprehensive security system. 6. Quick Installation Another advantage of razor mesh fencing is the ease and speed of installation. This factor can significantly reduce labor costs and allows for rapid deployment of security measures, which is particularly essential in urgent situations. Conclusion Razor mesh fencing is a practical and effective security solution for a variety of properties. With its unique design, it offers an unparalleled level of protection while remaining visually transparent. When considering options for securing a property, it is essential to weigh the benefits of razor mesh fencing, from its durability and versatility to the enhanced security it provides. As the needs for safety and security continue to evolve, razor mesh fencing stands out as a modern answer to safeguarding homes, businesses, and public facilities alike. Embracing this innovative fencing solution can not only bring peace of mind to property owners but also significantly decrease the risks associated with unauthorized access.

- vierkante kopspijkers voor houten vloeren******Vierkante Houten Spijkers voor Houten Vloeren Een Complete Gids Houten vloeren zijn een populaire keuze in veel Nederlandse huizen, dankzij hun esthetische uitstraling en duurzaamheid. Bij het installeren van houten vloeren komt een belangrijk aspect kijken het gebruik van de juiste bevestigingsmiddelen. Vierkante houten spijkers zijn een uitstekende optie voor dit doel. In dit artikel bespreken we alles wat je moet weten over vierkante spijkers voor houten vloeren, inclusief hun voordelen, toepassingen en installatie. Wat zijn vierkante spijkers? Vierkante spijkers zijn spijkers met een vierkante dwarsdoorsnede, wat ze onderscheidt van de meer traditionele ronde spijkers. Dit ontwerp zorgt ervoor dat ze beter gripen in het hout en zo een stevige verbinding creëren. Ze zijn vaak gemaakt van staal en zijn verkrijgbaar in verschillende maten en lengtes, afhankelijk van de specifieke toepassing. Voordelen van vierkante spijkers 1. Sterkte en stabiliteit Het belangrijkste voordeel van vierkante spijkers is hun vermogen om een stevige verbinding te creëren. Door hun ontwerp kunnen ze beter in het hout 'grijpen', waardoor ze minder kans hebben om los te raken in de loop der tijd. Dit is vooral belangrijk voor houten vloeren, die onderhevig zijn aan belasting en beweging. 2. Weerstand tegen splijten In tegenstelling tot ronde spijkers, die soms kunnen leiden tot splijten van het hout, zijn vierkante spijkers ontworpen om schade aan het materiaal te minimaliseren. Dit betekent dat je minder kans hebt op barsten of scheuren in je mooie houten vloer. 3. Esthetiek Voor sommige huiseigenaren is de esthetische uitstraling van de bevestigingsmiddelen belangrijk. Vierkante spijkers kunnen een rustiek en authentiek gevoel aan een houten vloer geven, wat goed past bij traditionele of ambachtelijke ontwerpen. Toepassingen van vierkante spijkers square head nails for wood floors Vierkante spijkers worden voornamelijk gebruikt voor het bevestigen van houten planken op een houten ondervloer. Ze zijn ideaal voor zowel massief houten vloeren als voor samengestelde houten vloeren. Daarnaast worden ze ook gebruikt in meubelmakerij en andere houtbewerkingstoepassingen waar sterke verbindingen noodzakelijk zijn. Installatie van vierkante spijkers Het installeren van vierkante spijkers kan aanzienlijke voordelen bieden, maar het is belangrijk om het juiste proces te volgen om ervoor te zorgen dat de spijkers effectief en veilig worden aangebracht 1. Voorboren In veel gevallen is het aan te raden om eerst te voorboren. Dit kan helpen om splijten en andere schade aan het hout te voorkomen. Kies een boor die iets smaller is dan de spijker om de perfecte pasvorm te garanderen. 2. Plaatsing Plaats de vierkante spijker in het voorgeboorde gat en gebruik een hamer of een spijkerpistool om deze in het hout te slaan. Zorg ervoor dat de spijker recht staat en dat je voldoende kracht uitoefent om deze volledig in het hout te duwen. 3. Afwerking Na het inslaan van de spijkers, kun je de koppen indien nodig inslaan en vervolgens het oppervlak van de vloer afwerken met een geschikte beits of vernis. Dit helpt om de spijkers te camoufleren en de algehele uitstraling van de vloer te verbeteren. Conclusie Vierkante houten spijkers zijn een geweldige keuze voor iedereen die houten vloeren installeert of renoveert. Hun unieke ontwerp biedt tal van voordelen, waaronder verbeterde grip, weerstand tegen splijten en een aantrekkelijke esthetiek. Door de juiste technieken toe te passen bij het installeren van deze spijkers, kun je ervoor zorgen dat je vloer niet alleen mooi is, maar ook duurzaam en stevig. Of je nu een nieuwe vloer legt of een bestaande vloer opknapt, overweeg om vierkante spijkers te gebruiken voor de beste resultaten.

- Spiral Barbed Wire Fence - Durable Security Solutions for Your Property******The Benefits of Spiral Barbed Wire Fences Spiral barbed wire fences are becoming increasingly popular for property security and livestock management. Combining functionality with robustness, these fences are designed to deter intruders and keep animals safely contained. In this article, we explore the advantages of using spiral barbed wire fences. One of the primary benefits of spiral barbed wire is its enhanced security features. The twisted spiral design creates multiple barriers, making it much harder for potential trespassers to climb over or cut through . Traditional barbed wire can be effective, but the spiral pattern adds an extra layer of difficulty for unauthorized entry. This makes spiral barbed wire fences particularly suitable for high-security areas, such as military installations, prisons, and border control. Moreover, spiral barbed wire is incredibly durable. Made from high-quality materials, these fences are designed to withstand harsh weather conditions and resist rust and corrosion. This longevity means lower maintenance costs over time and ensures that the fence will remain effective in protecting your property or livestock for years to come. Additionally, the spiral design allows for easy installation atop existing fences, enhancing security without the need for complete replacement. spiral barbed wire fence In agricultural settings, spiral barbed wire fences play a vital role in livestock management. They help contain animals, preventing them from wandering off and reducing the risk of accidents on roadways. The sharp barbs deter animals from pushing against the fence, thereby minimizing the chances of them escaping. This is particularly important for farmers and ranchers who aim to maintain the integrity of their livestock and farmland. Aesthetically, while wire fences may not be the most visually appealing option, the spiral design can present a neater appearance than traditional barbed wire. The uniformity of the spiral adds a certain visual coherence, making it a suitable choice for both rural and semi-urban settings. Lastly, spiral barbed wire fences are versatile. They can be used in various environments, from agricultural fields and residential properties to industrial complexes. Their adaptability ensures that they meet a wide range of security and containment needs. In conclusion, spiral barbed wire fences offer a compelling solution for those looking to enhance security and manage livestock effectively. Their durability, effectiveness, and versatile applications make them a sound investment, safeguarding both property and peace of mind. Whether for agricultural or industrial use, these fences are undoubtedly a wise choice in today's security-conscious world.

- Top Manufacturers of Iron Nails for Quality and Durability in Construction******The Landscape of Iron Nails Manufacturers A Comprehensive Overview Iron nails have been fundamental components in construction, carpentry, and various other industries for centuries. These seemingly simple fasteners play a critical role in ensuring the structural integrity of numerous products, from furniture to roofing. In this article, we will explore the landscape of iron nails manufacturers, discussing their production processes, market trends, and sustainability efforts. Understanding Iron Nails Iron nails are typically made from ferrous metals, primarily iron, and are designed to hold materials together. They can come in various shapes and sizes, and their applications include framing, roofing, and woodworking, among others. The manufacturing process involves the extraction of iron ore, which is then smelted and refined to produce raw iron. This raw iron is subsequently shaped into nails using methods such as forging or casting. The Manufacturing Process The manufacturing of iron nails can be broadly divided into several key stages 1. Material Selection High-quality iron or steel is selected, with considerations for tensile strength and corrosion resistance. 2. Melting and Refining The chosen metal is melted in a furnace and refined to remove impurities. This stage ensures that the final product meets industry standards. 3. Forming and Shaping The molten metal is then poured into molds or formed into wire, which is cut to the desired length . Advanced manufacturers often utilize automated machinery to enhance precision and uniformity. 4. Finishing After shaping, nails are subjected to processes like heat treatment, galvanization, or coating to improve durability and resistance to rust. 5. Quality Control Before packaging, each batch undergoes rigorous quality control to ensure that the nails meet specified standards, including tensile strength and length accuracy. iron nails manufacturers Market Trends The iron nails market is influenced by several trends, reflecting changes in consumer needs and advancements in technology. One significant trend is the rising demand for eco-friendly materials. As industries shift towards sustainable practices, manufacturers are exploring ways to reduce their carbon footprint. This includes using recycled materials in the production of iron nails and implementing energy-efficient manufacturing processes. Additionally, the global construction boom has spurred the demand for iron nails, particularly in developing countries. Rapid urbanization and infrastructure development projects have led to increased consumption in residential and commercial construction. Manufacturers are responding by expanding their production capacities and diversifying their product lines to include specialized nails designed for specific applications. The Role of Technology The integration of technology in nail manufacturing has transformed traditional practices. Automation and robotics have streamlined production lines, significantly improving efficiency and reducing labor costs. Furthermore, advancements in computer-aided design (CAD) have enabled manufacturers to innovate their products, creating nails that better serve specific construction needs. 3D printing technology is also emerging as a potential game-changer for iron nails. With the ability to produce complex shapes and custom designs on demand, manufacturers may soon offer tailored solutions that enhance the performance and functionality of nails in various applications. Sustainability Efforts As consumers become more environmentally conscious, iron nails manufacturers are feeling the pressure to adopt sustainable practices. Many are investing in research and development to create eco-friendly coatings and treatments that minimize environmental impact. Additionally, several manufacturers are committed to recycling scrap metal from production processes, further reducing waste and conserving resources. Some companies are also focusing on enhancing the lifespan of their products to ensure reduced frequency of replacement, which contributes to overall sustainability. By emphasizing quality and durability, manufacturers not only serve their customers better but also align with the growing trend towards responsible consumption. Conclusion In conclusion, the landscape of iron nails manufacturers is one marked by a blend of traditional craftsmanship and innovative technologies. As the demand for iron nails continues to rise, manufacturers are adapting by embracing sustainable practices, leveraging technology, and responding to market trends. These efforts not only enhance the quality and efficiency of nail production but also contribute to a more sustainable future in construction and manufacturing. Whether through eco-friendly materials or advanced manufacturing techniques, the evolution of iron nails is an exciting space to watch in the coming years.

- pvc coated hexagonal wire mesh******The Versatility of PVC Coated Hexagonal Wire Mesh In recent years, the demand for durable, versatile, and aesthetically pleasing fencing solutions has increased significantly across various industries. One product that has gained immense popularity is the PVC coated hexagonal wire mesh. This unique mesh combines the strength and flexibility of steel with the protective and aesthetic qualities of PVC (Polyvinyl Chloride) coating, making it an ideal choice for a wide range of applications in agriculture, construction, and landscaping. What is PVC Coated Hexagonal Wire Mesh? PVC coated hexagonal wire mesh is made from high-quality steel wire that is woven into a hexagonal shape, resembling a beehive structure. After forming the wire mesh, it is coated with a layer of PVC to enhance its durability and resistance to environmental factors. The coating not only protects the mesh from rust and corrosion but also adds a vibrant color choice, making it visually appealing for various uses. Applications in Agriculture One of the primary applications of PVC coated hexagonal wire mesh is in the agricultural sector. Farmers and horticulturists often use this type of mesh for constructing protective barriers around crops. Its hexagonal shape allows for improved visibility and airflow while offering sufficient strength to keep out pests and larger animals. In addition, PVC coated mesh is used for creating enclosures for chickens, rabbits, and other small animals. The coated surface ensures that the mesh remains safe and non-toxic for animals, which is crucial in farming practices. Its resilience against harsh weather conditions makes it a reliable choice for outdoor use, ensuring the safety and security of livestock and crops. Construction and Fencing Beyond agriculture, PVC coated hexagonal wire mesh has become an excellent solution for construction and outdoor fencing projects. Builders often use this mesh for temporary fencing around construction sites to enhance safety and security. It acts as a barrier, preventing unauthorized access while allowing visibility, which is essential for maintaining a safe working environment. pvc coated hexagonal wire mesh Moreover, the aesthetic attributes of PVC coated wire mesh make it an attractive option for garden fencing and landscape features. Homeowners can create beautiful and functional boundaries around their properties while ensuring that the fencing method is durable and long-lasting. The variety of colors available in PVC coating allows customers to match their fencing with their landscape design seamlessly. Advantages of PVC Coated Hexagonal Wire Mesh 1. Durability The PVC coating provides an extra layer of protection against rust, corrosion, and UV degradation, extending the lifespan of the wire mesh significantly compared to uncoated alternatives. 2. Aesthetic Appeal With various color options available, PVC coated hexagonal wire mesh offers an attractive solution for those looking to enhance the appearance of their gardens, farms, or construction sites. 3. Versatility Its uses span multiple industries, making it a versatile solution for agriculture, construction, landscaping, and even wildlife protection. 4. Lightweight and Flexible Despite its strength, PVC coated hexagonal wire mesh is lightweight and can be easily manipulated to fit various applications, from fencing to protective structures. 5. Cost-Effective The long lifespan and low maintenance of PVC coated mesh make it a cost-effective investment for both agricultural and residential projects. Conclusion PVC coated hexagonal wire mesh stands out as a durable, versatile, and aesthetically pleasing solution for a myriad of applications. Whether safeguarding crops, securing construction sites, or enhancing landscaping efforts, this innovative product offers a perfect blend of functionality and style. As industries continue to recognize the benefits of this mesh, it is likely to maintain its status as a preferred fencing and protective solution for many years to come. With its numerous advantages and practical uses, PVC coated hexagonal wire mesh is truly a remarkable example of modern engineering and design that meets diverse needs in today’s world.

- Sustainable Innovations in Wooden Fasteners for Eco-Friendly Construction Projects******The Rise of Lignoloc Wooden Nails A Sustainable Alternative In recent years, the construction industry has seen significant shifts toward more sustainable practices. Among the innovative materials gaining traction is lignoloc wooden nails. These eco-friendly nails are crafted from sustainable wood sources, providing a compelling alternative to traditional metal fasteners. As awareness of environmental concerns continues to rise, lignoloc wooden nails present a practical and sustainable option for builders and DIY enthusiasts alike. What Are Lignoloc Wooden Nails? Lignoloc wooden nails are precision-engineered fasteners made from various types of wood, primarily sourced from responsibly managed forests. Unlike traditional nails which are usually made from steel or other metals, lignoloc nails offer a variety of advantages, particularly in terms of sustainability and aesthetics. The production of lignoloc nails does not require the high energy and resource input associated with metal manufacturing, making it a low-impact choice for construction projects. Environmental Benefits The environmental benefits of using lignoloc wooden nails are manifold. Firstly, they are made from renewable resources, which means that their production does not deplete non-renewable resources. Furthermore, because they are composed entirely of wood, lignoloc nails are biodegradable and can decompose naturally at the end of their life cycle, unlike metal fasteners that can contribute to landfill waste. Additionally, the choice of using sustainable wood sources helps in the maintenance of healthy forests. Many manufacturers adhere to strict sustainability standards, ensuring that their wood is harvested responsibly and supporting reforestation efforts. This holistic approach to sourcing and production resonates with modern consumers who are increasingly aware of the environmental issues associated with conventional manufacturing practices. Performance and Durability lignoloc wooden nails One might wonder if lignoloc wooden nails can match the performance of traditional metal nails. Interestingly, recent advancements in wood technology have led to the development of wooden nails that provide excellent structural integrity. Lignoloc nails are designed to withstand a variety of stresses, making them suitable for various applications, from woodworking to construction. They are engineered to ensure strong connections, reducing the risk of splitting or breaking under pressure. Moreover, lignoloc nails offer excellent resistance to weather elements, particularly when treated with protective coatings. This makes them viable for outdoor projects as well, where exposure to moisture and temperature fluctuations could otherwise compromise the integrity of traditional fasteners. Aesthetics and Versatility Beyond their functional benefits, lignoloc wooden nails add an aesthetically pleasing touch to projects, appealing to those who value natural materials. The warm tones of wood create a cozy and organic feel, making them a perfect choice for furniture, interior finishes, and decorative elements. Their versatility allows them to be used in various applications, including cabinetry, flooring, and outdoor construction. Additionally, lignoloc nails are easy to work with, which appeals to DIY enthusiasts and professional builders alike. They can be used with standard tools and require no special techniques, making them accessible for a wide range of users. Conclusion As the push for sustainable practices in construction continues to gain momentum, lignoloc wooden nails stand out as a viable alternative to traditional metal fasteners. Their environmental benefits, combined with their performance, durability, and aesthetic appeal, make them an attractive option for a variety of projects. By opting for lignoloc nails, builders and DIYers not only contribute to reducing their environmental footprint but also embrace an innovative and stylish choice in their construction endeavors. With the ongoing advancements in wood technology and sustainable practices, the future of building materials looks promising with lignoloc wooden nails leading the way.

- Razor Wire Rolls for Enhanced Security Solutions in Various Applications******The Importance of Razor Wire Rolls in Security Applications Razor wire rolls, often synonymous with heightened security measures, have become increasingly prevalent in various sectors that prioritize safety and protection. This formidable fencing solution plays a critical role in deterring unauthorized access and securing perimeters around sensitive areas. In this article, we will explore the design, applications, advantages, and considerations related to razor wire rolls, highlighting their significance in modern security infrastructures. Understanding Razor Wire Razor wire, also known as barbed tape or Razor ribbon, is a type of fencing material made from sharp-edged steel strips or wire that has been coiled into a roll. The design features tightly spaced barbs or blades that can inflict severe injury, making it an effective deterrent against trespassers. This formidable barrier is often used in conjunction with other security measures to create a multi-layered defense system. Applications of Razor Wire Rolls Razor wire rolls are widely used across various sectors, including 1. Military Facilities Razor wire is commonly utilized in military installations to protect sensitive areas from intrusion by unauthorized personnel. 2. Correctional Institutions Prisons and jails frequently employ razor wire as part of their perimeter security, helping to prevent escapes and unauthorized access. 3. Industrial Sites Factories and warehouses often face the risk of theft or vandalism. The installation of razor wire barriers helps safeguard valuable assets and equipment. 4. Border Security Razor wire rolls are frequently deployed at national borders to prevent illegal crossings and smuggling activities . 5. Residential Security While less common, some homeowners opt for razor wire as an additional security measure, particularly in high-crime areas. Advantages of Razor Wire razor wire roll The use of razor wire rolls offers several advantages that contribute to their popularity in security applications - Deterrence The sharp blades and menacing appearance of razor wire act as a visual deterrent, discouraging potential intruders from attempting to breach the perimeter. - Durability Made from galvanized steel, razor wire is designed to withstand harsh weather conditions and resist corrosion, ensuring long-lasting effectiveness. - Cost-Effectiveness Compared to alternative security solutions such as electric fencing or surveillance systems, razor wire is relatively inexpensive to install and maintain, making it an attractive option for budget-conscious entities. - Easy Installation Razor wire rolls are lightweight and easy to handle, facilitating quick installation around various types of perimeters. Considerations for Installation While razor wire offers significant benefits, there are also considerations that must be addressed before installation - Legal Regulations Depending on the region and type of property, there may be legal restrictions regarding the height and appearance of fencing materials, including razor wire. It is essential to consult local regulations before proceeding. - Safety Concerns The primary purpose of razor wire is to deter trespassers, but it can also pose risks to individuals who may inadvertently come into contact with it. Proper signage and clear boundaries should be established to mitigate these dangers. - Aesthetic Impact In residential areas, the installation of razor wire may not be well-received by neighbors due to its intimidating appearance. Alternatives that provide security while maintaining a more welcoming aesthetic may be worth considering. Conclusion Razor wire rolls are a vital element in the arsenal of security measures available today. Their effectiveness in deterrence, durability, and cost-effectiveness make them a preferred choice for a variety of applications. However, it is crucial to consider legal, safety, and aesthetic factors when integrating razor wire into security strategies. As threats to security evolve, so too will the methods of protection, and razor wire will continue to play a significant role in safeguarding people, property, and sensitive areas around the world. Whether in military installations, correctional facilities, or industrial sites, razor wire remains a steadfast guardian in the realm of security.

- t post barbed wire fence******The Enduring Symbolism of Barbed Wire Fences In the tapestry of modern civilization, few structures evoke such a potent mixture of utility, symbolism, and controversy as the barbed wire fence. First invented in the late 19th century, barbed wire has transformed from a practical invention into an enduring emblem of division, confinement, and regulation. This article explores the multifaceted role of barbed wire fences in society, delve into their historical significance, and analyze their contemporary implications. The Enduring Symbolism of Barbed Wire Fences However, while it served a practical purpose, barbed wire also became a tool of control. Its introduction laid the groundwork for the transformation of vast open spaces into private land, representing a shift towards a more structured society. The era of the open range was replaced by fenced homesteads, which created borders and property lines that shaped economics, community structures, and even social relations. Barbed wire fences became visual markers of ownership and authority, defining who could access which land and under what circumstances. t post barbed wire fence Fast forward to the 20th century, and the symbolism of barbed wire evolved even further. During World War I and World War II, barbed wire gained notoriety as a tool of restriction and confinement. It was used to establish prison camps and internment facilities, where the suffering of many individuals marked a dark chapter in human history. In this context, the fence morphed from a symbol of agricultural progress into one of suffering, separation, and dehumanization. The sight of barbed wire, intertwined with images of soldiers and refugees, has become synonymous with conflict, oppression, and trauma. In contemporary society, barbed wire continues to be a polarizing symbol. It can often be found along geopolitical borders, particularly in regions rife with conflict. The fences erected across the U.S.-Mexico border are a prime example, constructed with the stated purpose of curbing illegal immigration and drug trafficking. However, they also reflect deeper societal issues, including xenophobia and the fear of the other. The barbed wire fence here is not merely a physical barrier; it serves as a representation of the ideologies that permeate discussions about immigration and national identity. Should they symbolize safety, or do they represent division and hostility? This ongoing debate illustrates how barbed wire retains its power as a symbol of social and political tensions. Apart from geopolitical boundaries, barbed wire also finds its place in urban environments, where it is used to secure properties, discourage trespassing, and protect against vandalism. In this context, the barbed wire fence again becomes a symbol—this time of safety for some and of exclusion for others. For many, encountering a spiked fence signals a lack of welcome, a reminder that some spaces are not meant for everyone. The physical presence of these barriers often correlates with social disparities, underscoring issues of inequality, gentrification, and social stratification. In conclusion, the barbed wire fence embodies a rich tapestry of meanings. From its origins in agriculture to its representation of conflict and division, this simple yet powerful invention encapsulates critical themes in human history—ownership, authority, suffering, safety, and exclusion. As society continues to grapple with issues of division and identity, the barbed wire fence remains a poignant reminder of the physical and metaphorical boundaries we create. Whether viewed as a tool of practicality or a harbinger of hostility, its impact and symbolism will likely continue to provoke thought and inspire debate for generations to come. The question we must ponder is what do our fences say about who we are and who we aspire to be?

- Vintage Barbed Wire Collection Inspired by Rustic Charm and Historical Significance******The Timeless Charm of Vintage Barbed Wire Barbed wire, a seemingly simple invention, has played a crucial role in shaping the landscapes and the livelihoods of countless communities throughout history. While its primary purpose may have been to contain livestock and mark property boundaries, the aesthetic allure of vintage barbed wire transcends its functional origins. Today, it serves as a nostalgic reminder of a bygone era, evoking memories of rugged frontier life and the enduring spirit of the American West. The history of barbed wire dates back to the late 19th century, emerging as ranchers sought efficient ways to manage cattle on the expansive prairies. Prior to its invention, the challenges of keeping livestock penned were daunting. Traditional wooden fences were costly and often impractical in arid regions where timber was scarce. The introduction of barbed wire revolutionized land management, allowing ranchers to establish effective barriers at a fraction of the cost. The early designs of barbed wire were as varied as the individuals who crafted them. Many barbed wire types were patented, each with unique features and aesthetics, reflecting the creativity and ingenuity of their inventors. Today, these vintage designs are celebrated, cherished not just for their functionality, but for their craftsmanship. The intricate patterns of twisted wire and sharp barbs tell stories of resilience and resourcefulness, showcasing the innovative spirit of those who lived in a time of expansion and adventure. vintage barbed wire Collectors and enthusiasts have developed a deep appreciation for vintage barbed wire . Antique shows and farmer’s markets often feature booths dedicated to these relics, attracting both seasoned collectors and curious newcomers. For many, collecting barbed wire is not merely a hobby; it is a way to connect with the past, preserving pieces of history that might otherwise be forgotten. Each coil and piece of twisted metal carries with it tales of the land, the hardships faced by ranchers, and the communities that founded them. Beyond the realm of collectors, vintage barbed wire has also captured the attention of artists and designers. The aesthetic value of aged and rusted wire is often leveraged in home decor, garden design, and art installations. The rugged texture and earthy tones of weathered barbed wire can enhance the rustic charm of a space, bringing an essence of the outdoors indoors. From serving as unique planters to creating striking wall art, vintage barbed wire has found new life in contemporary design, showcasing its versatility and enduring appeal. Moreover, barbed wire serves as a poignant symbol of human ingenuity and the complexities of progress. While it was developed primarily for practical purposes, its historical context invites discussions on themes such as land ownership, conflict, and the fine balance between progress and preservation. In an era where the conversation surrounding environmental sustainability and land use is more relevant than ever, vintage barbed wire reminds us of the need to honor our past while looking forward to the future. In conclusion, vintage barbed wire is much more than a tool for keeping livestock in check; it represents a rich tapestry of history, creativity, and resilience. Whether seen in the hands of a collector, as part of a home decor scheme, or analyzed through the lens of history, it embodies a unique blend of functionality and artistry. As we continue to explore and celebrate our shared heritage, vintage barbed wire will remain a timeless icon, connecting us to the spirit of those who came before us and the landscapes they shaped.

- Sharp blade wire used for security purposes to prevent unauthorized access.******Razor blade wire, also known as barbed tape, is a type of security fencing that is made up of sharp metal blades or barbs attached at regular intervals along a strand of metal wire. This type of fencing is commonly used for high-security facilities such as prisons, military compounds, and government buildings. The sharp blades of razor blade wire serve as a strong deterrent to potential intruders, as they can cause serious injury or even death if someone attempts to climb over or cut through the fence. The installation of razor blade wire is a cost-effective way to enhance the security of a perimeter without the need for expensive electronic surveillance systems. Razor blade wire is designed to be difficult to cut or tamper with, making it an effective barrier against unauthorized access. The sharp blades are typically made of galvanized steel or stainless steel, which ensures durability and resistance to corrosion. In addition, the wire strands are often twisted together to increase the strength and stability of the fence. One of the key benefits of razor blade wire is its versatility in terms of installation. It can be easily attached to existing fences or walls, or it can be used as a standalone barrier . The flexibility of razor blade wire allows it to be customized to fit the specific security needs of a facility, whether it be a small residential property or a large industrial complex razor blade wire . In addition to its security benefits, razor blade wire also has a visual deterrent effect. The sharp blades are highly visible and intimidating, serving as a clear warning to potential trespassers. This added layer of security can help to reduce the likelihood of break-ins or unauthorized access, providing peace of mind to property owners and occupants. While razor blade wire is an effective security measure, it is important to ensure that it is installed properly to maximize its effectiveness. Professional installation is recommended to ensure that the razor blade wire is securely attached and that all safety precautions are taken during the process. Overall, razor blade wire is a reliable and cost-effective security solution for protecting facilities against unauthorized access. Its sharp blades and durable construction make it a highly effective deterrent to potential intruders, providing peace of mind to property owners and ensuring the safety of occupants. With proper installation and maintenance, razor blade wire can help to enhance the security of any perimeter.

- net fencing wire******Understanding Net Fencing Wire A Guide for Modern Farmers In the realm of modern agriculture, net fencing wire has emerged as an essential tool for farmers and landowners. This fencing solution is not only practical but also versatile, offering numerous benefits for managing livestock and protecting crops. This article explores the various aspects of net fencing wire, its applications, and its advantages. What is Net Fencing Wire? Net fencing wire, often referred to simply as “netting,” consists of interwoven wire strands that create a sturdy, flexible barrier. Typically made from either galvanized steel or high-tensile wire, this type of fencing is designed to withstand the rigors of outdoor environments. The netting can be configured in various dimensions to accommodate different agricultural needs, making it a popular choice for both large farms and small homesteads. Applications in Agriculture One of the primary applications of net fencing wire is in livestock management. Farmers use this fencing to create secure enclosures for animals, preventing them from straying onto roads or other dangerous areas. The closely spaced wires in netting are particularly effective at keeping smaller animals, such as goats and sheep, contained while ensuring that larger animals, like cows and horses, cannot escape. In addition to livestock management, net fencing wire is also widely used for crop protection . Farmers can employ netting to safeguard crops from wildlife that may otherwise damage or consume fruits, vegetables, and flowers. Netting can be placed over garden beds or around orchards to create a physical barrier that deters pests without the need for harmful chemicals or traps. net fencing wire Advantages of Using Net Fencing Wire The benefits of net fencing wire are numerous. First and foremost, its durability means that it can withstand harsh weather conditions, including high winds, heavy rain, and extreme temperatures. Galvanized options offer extra resistance against rust and corrosion, extending the lifespan of the fencing significantly. Furthermore, net fencing wire is relatively easy to install and maintain. Unlike traditional wooden or barbed wire fencing, which may require strong posts and regular repairs, netting can often be set up with minimal tools and expertise. This efficiency is particularly important for farmers who need to allocate their time and resources effectively. Another advantage is the fencing’s adaptability. Farmers can choose from a range of heights and styles, ensuring that netting meets their specific needs. Some types are designed for electric fencing applications, providing an additional layer of security against potential breaches. Finally, net fencing wire is environmentally friendly. By reducing the need for chemical deterrents and promoting the welfare of livestock, netting presents a sustainable option for agricultural practices. Conclusion In conclusion, net fencing wire is an invaluable resource for modern farmers. Its versatility allows for effective livestock management and crop protection, while its durability and ease of use make it a practical choice for diverse agricultural applications. As the agricultural landscape continues to evolve, net fencing wire will undoubtedly remain a key component in promoting efficient and sustainable farming practices. Embracing such innovations not only enhances productivity but also contributes to the broader goals of environmental conservation and responsible land stewardship.

- The Essential Benefits of Iron Nails******Iron nails are a fundamental component in construction and woodworking, renowned for their strength and versatility. Whether you're a professional contractor or a DIY enthusiast, understanding the price of iron nails , the different types available, and specific options like black iron nails and Chinese iron nails will help you make informed decisions for your projects. Price of Iron Nails: Affordable Options for Every Budget When considering materials for your construction needs, the price of iron nails is an important factor. Iron nails are generally affordable, making them a cost-effective choice for a wide range of applications. Prices can vary based on factors such as size, type, and quantity purchased. Bulk purchases often come with significant discounts, allowing you to save even more. By comparing prices from various suppliers, you can find high-quality iron nails that fit your budget while ensuring durability and reliability in your projects. Black Iron Nails: A Stylish and Functional Choice Black iron nails are not only functional but also add a touch of elegance to your projects. These nails are often coated with a black finish, which not only enhances their aesthetic appeal but also provides additional protection against rust and corrosion. Black iron nails are ideal for a variety of applications, including woodworking, home repairs, and decorative projects. Their strong holding power ensures that your structures remain secure while maintaining a stylish appearance. Whether you’re building furniture or framing a wall, black iron nails are a fantastic choice that combines strength with beauty. Types of Iron Nails: Finding the Right Fit for Your Project There are several types of iron nails , each designed for specific applications. Common types include common nails, finish nails, and roofing nails. Common nails are versatile and used in general construction, while finish nails are smaller and ideal for detailed work, providing a smooth finish without splitting the wood. Roofing nails feature a wide head for securing shingles and other roofing materials. Understanding the different types of iron nails available allows you to select the best option for your specific needs, ensuring optimal performance in your projects. Chinese Iron Nails: Quality and Affordability Combined Chinese iron nails are gaining popularity for their quality and competitive pricing. Manufactured using reliable processes, these nails meet international standards and offer excellent strength and durability. Chinese iron nails are available in various sizes and types, making them suitable for a wide range of construction and woodworking applications. By choosing Chinese iron nails , you can benefit from cost-effective solutions without compromising on quality. They are an excellent choice for both professional contractors and DIY enthusiasts looking for dependable materials at an affordable price. Conclusion: Choose Iron Nails for Strength and Versatility In conclusion, iron nails are an indispensable resource in construction and woodworking projects, offering strength, versatility, and affordability. By considering the price of iron nails , exploring options like black iron nails , understanding the various types available, and recognizing the value of Chinese iron nails , you can make informed decisions that enhance your projects. Invest in high-quality iron nails for your next endeavor and experience the durability and reliability they provide, ensuring your structures stand the test of time!

- Installer une clôture en bois à panneaux divisés étape par étape******Installer une Clôture en Bois de Type Split Rail Guide Complet La clôture en bois de type split rail est un choix populaire pour de nombreux propriétaires cherchant à délimiter leur propriété tout en ajoutant une touche d'esthétique naturelle. Ce type de clôture est non seulement fonctionnel, mais il apporte également un charme rustique et authentique à n'importe quel paysage. Si vous envisagez d'installer une clôture de ce type, voici un guide pratique pour vous aider à mener à bien ce projet. Matériaux et Outils Nécessaires Avant de commencer l'installation, il est essentiel de rassembler les matériaux et outils nécessaires. Vous aurez besoin de - Panneaux de clôture en bois de type split rail - Boulons et vis en acier galvanisé - Un niveau à bulle - Une pelle ou une tarière pour creuser les trous - Un marteau - Une scie à main ou une scie circulaire (si des ajustements sont nécessaires) - Un mètre à ruban - Des gants de travail Étapes de l’Installation 1. Planification et Mesurage Avant toute chose, il est crucial de planifier votre clôture. Définissez la zone que vous souhaitez délimiter et mesurez avec précision. Utilisez un mètre à ruban pour prendre des mesures de la longueur de la clôture que vous souhaitez installer. 2. Marquage du Terrain Avec un bâton ou une corde, marquez le tracé de votre clôture. Cela vous aidera à visualiser l’espace et à éviter toute confusion lors de l’installation. 3. Creuser les Trous Pour chaque poteau de clôture, vous devrez creuser un trou d’environ 60 à 90 cm de profondeur, selon la taille de vos poteaux . Assurez-vous que les trous sont espacés d'environ 2,4 à 3 mètres les uns des autres. install split rail fence 4. Installer les Poteaux Placez le premier poteau dans le trou et utilisez un niveau à bulle pour vous assurer qu’il est droit. Remplissez le trou avec du béton ou de la terre, en veillant à bien tasser le sol autour du poteau pour qu'il soit bien stable. 5. Fixer les Rails Une fois les poteaux en place et le béton durci (si vous avez utilisé du béton), commencez à fixer les rails. Selon le type de clôture que vous avez choisi, vous pouvez avoir un rail inférieur, un rail supérieur et un ou plusieurs rails intermédiaires. Utilisez des boulons ou des vis en acier galvanisé pour assurer une fixation solide. 6. Vérification et Ajustements Une fois tous les rails installés, prenez du recul et vérifiez si tout est bien aligné. Faites des ajustements si nécessaire. Cela garantira un aspect soigné et professionnel à votre clôture. 7. Finition Enfin, vous pouvez appliquer une finition sur le bois pour le protéger des intempéries et prolonger sa durée de vie. Une peinture ou une teinture pour bois spécialisée aidera à préserver la beauté naturelle de votre clôture. Entretien de la Clôture Après l’installation, un entretien régulier est crucial pour préserver l’intégrité de votre clôture en bois. Inspectez-la chaque année pour détecter d'éventuels signes de détérioration ou de dommages causés par les insectes. Il est conseillé de redonner un coup de peinture ou de teinture tous les deux à trois ans. Conclusion Installer une clôture en bois de type split rail peut sembler une tâche ardue, mais avec une bonne préparation et les bons outils, cela peut être un projet gratifiant qui améliorera l'apparence de votre propriété. Que ce soit pour définir votre espace ou simplement pour embellir votre jardin, cette clôture apportera un charme indéniable. N’oubliez pas de respecter les réglementations locales concernant les clôtures pour éviter tout désagrément. Profitez de votre nouveau projet de clôture !

- Knappet ledningsmesh-produsent******Produsent av Strikket Trådmessing Kvalitet og Innovasjon I dagens moderne industri blir strikket trådmessing i økende grad anerkjent for sine mange fordeler og bruksområder. Som en produsent av strikket trådmessing, har vi et sterkt fokus på kvalitet, innovasjon og kundetilfredshet. Dette bidrar til å skape løsninger som møter behovene til ulike industrier, fra byggebransjen til kunstneriske applikasjoner. Hva er strikket trådmessing? Strikket trådmessing er laget ved å kombinere tynn tråd i et strikket mønster, noe som gir materialet både fleksibilitet og styrke. Denne typen mesh er kjent for sin høye motstand mot korrosjon, samt sin evne til å håndtere ekstreme temperaturer, noe som gjør den ideell for forskjellige industrielle applikasjoner. Den er lett og kan tilpasses i henhold til kundens spesifikasjoner, noe som gjør den til et populært valg i mange prosjekter. Fordeler med strikket trådmessing En av de mest fremtredende fordelene ved strikket trådmessing er dens allsidighet. Den kan brukes til alt fra sikkerhetsgitter og skjermer til industrielle filtre og akustiske paneler. Strikket trådmessing gir også utmerket ventilasjon og lysgjennomslipp, noe som er essensielt i mange applikasjoner. I tillegg er den estetiske appell som denne typen mesh kan tilby, en fordel i design og arkitektur, hvor både funksjon og skjønnhet er viktige. Kvalitetssikring og bærekraft knitted wire mesh manufacturer Som en ansvarlig produsent er vi forpliktet til høy kvalitet og bærekraft i vår produksjonsprosess. Vi benytter oss av førsteklasses materialer og moderne produksjonsteknikker for å sikre at vårt strikkede trådmessing oppfyller alle relevante standarder. Gjennom kontinuerlig forskning og utvikling investerer vi i nye teknologier som forbedrer både kvalitet og effektivitet i produksjonen. I tillegg er vi bevisste på vårt miljøansvar. Ved å implementere bærekraftige produksjonsmetoder og minimere avfall, jobber vi aktivt for å redusere vårt karbonavtrykk. Dette er ikke bare en plikt, men også en del av vår bedriftskultur, som verdsetter både miljøet og samfunnets velvære. Partnerskap og tilpassede løsninger Vi forstår at hver kunde har unike behov, og derfor tilbyr vi skreddersydde løsninger for strikket trådmessing. Vårt erfarne team jobber tett med kunder for å utvikle spesifikasjoner og design som oppfyller deres individuelle krav. Gjennom partnerskap og samarbeid kan vi levere produkter som ikke bare er av høy kvalitet, men også kostnadseffektive. Konklusjon Som en ledende produsent av strikket trådmessing er vi stolte av vår evne til å levere produkter som kombinerer innovasjon, kvalitet og bærekraft. Enten du er i byggebransjen, design, eller industrisektoren, kan du stole på at våre løsninger vil møte dine behov. Vi er dedikert til å skape verdifulle partnerskap med våre kunder og ser frem til å bidra til deres suksess gjennom våre produkter og tjenester. Med vår fokus på kvalitet og tilpasning, er vi her for å støtte deg i hvert steg av prosessen. Ta kontakt med oss i dag for å lære mer om hva vi kan tilby!