floor board nail******The Importance of Floor Board Nails in Home Construction and Renovation When it comes to flooring, stability and durability are paramount. One of the often-overlooked heroes in ensuring the longevity and robustness of floor installations is the humble floor board nail. These specialized fasteners play a crucial role in securing floorboards, providing a solid foundation for our living spaces. In this article, we will delve into the significance of floor board nails, exploring their types, applications, and tips for proper installation. Understanding Floor Board Nails Floor board nails are specifically designed fasteners used to attach wooden floorboards to the subfloor or joists beneath. These nails are typically made of steel, which offers excellent strength and resistance to bending, ensuring that the floor remains intact even under heavy loads. Depending on the application, floor board nails may come in various lengths and diameters, allowing for flexibility based on the thickness of the flooring material used. Types of Floor Board Nails There are several types of nails used in flooring installations, each serving a distinct purpose. Some of the most common include 1. Clipped Head Nails These nails are designed with a smaller head, making them less visible when fully driven into the wood. They are ideal for applications where aesthetics are a concern, as they can be concealed under a smooth finish. 2. Ring Shank Nails Featuring a series of rings around the shaft, these nails provide superior holding power. The ringed design increases friction between the nail and the wood, making them less likely to pull out over time. They are particularly useful in high-traffic areas where floor movement is expected. 3. Spiked Nails These have a larger, spiked head and are often used when additional holding power is required. They are effective in securing thicker boards, ensuring that the floor remains stable even as it expands and contracts with changes in humidity. Applications of Floor Board Nails floor board nail The primary application of floor board nails is, of course, in securing floorboards to the subfloor. However, their usage can extend beyond just floor installations. Floor board nails are also essential in other woodwork applications, such as securing wooden beams, creating frameworks for cabinetry, and even in outdoor construction where wooden decks are involved. In newly constructed homes, proper installation of floor board nails is critical for ensuring a flat and even surface. Similarly, during renovations, replacing old, worn-out floorboards requires diligent attention to detail, as the quality of the nails used can significantly affect the end result. This is why choosing the right type of nail is crucial for both structural integrity and visual appeal. Tips for Proper Installation Installing floor board nails might seem straightforward, but a few best practices can lead to a more successful outcome 1. Pre-Drilling For hardwood floors, pre-drilling holes can prevent the wood from splitting, particularly in thinner sections. This ensures that the nail is driven in smoothly without damaging the adjacent wood. 2. Spacing Proper spacing between nails is essential. Generally, nails should be spaced every 6 to 8 inches to provide adequate support and prevent any sagging of the floorboards over time. 3. Driving Technique When hammering in nails, ensure that they are driven in straight and flush with the surface of the wood. Nails that are not fully sunk can become a tripping hazard and may detract from the overall appearance of the flooring. 4. Use of Nail Guns For larger projects, using a nail gun can speed up the installation process while also providing consistent depth and angle. Pneumatic nailers specifically designed for flooring applications are highly recommended. Conclusion In conclusion, floor board nails may seem like a minor detail in the grand scheme of home construction and renovation, yet their impact is significant. Choosing the appropriate type and ensuring proper installation can enhance the durability and aesthetics of your floors. By understanding the role of these fasteners and applying best practices in their use, homeowners and builders alike can achieve a solid and long-lasting foundation for any living space. Whether you're crafting a new floor or restoring an old one, remember that the integrity of your work often rests on the simplest of components—like the unassuming floor board nail._6ft chain link fencing

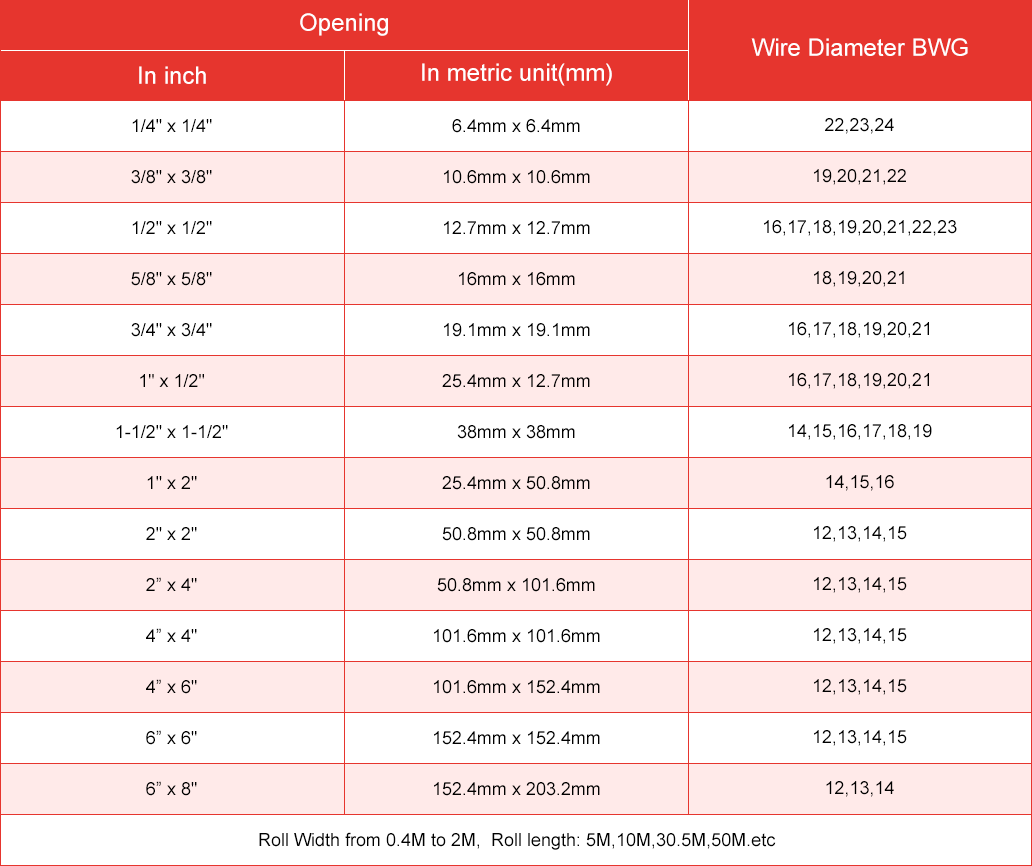

와이어 그물 사이즈

메쉬 와이어의 치수는 다양한 산업 분야에서 매우 중요한 요소로 작용합니다. 메쉬 와이어는 주로 금속으로 만들어지며, 다양한 크기와 형태로 제공됩니다. 이 기사에서는 메쉬 와이어의...

прадстаўшчыкаў прадстаўшчыкаў

Пастаўшчыкі металічнай сеткі ключ да надзейнасці і бяспекі Металічная сетка з'яўляецца адным з самых...

Estimating Costs for Chicken Wire Fencing Solutions and Considerations

Understanding the Cost of Chicken Wire Fencing When it comes to securing your property, especially f...

δίχτυ κοτόπουλου

Το Δίκτυο Κοτόπουλων Μια Καινοτόμος Λύση για τη Χέρσωση και την Εκτροφή Η εκτροφή κοτόπουλων αποτελε...

wire mesh fencing net price

Understanding Wire Mesh Fencing Net Prices When considering options for fencing, wire mesh fencing s...

Links

- mesh wire for fence******Understanding Mesh Wire for Fences A Comprehensive Overview When it comes to securing properties, delineating boundaries, or establishing safe enclosures for pets and livestock, mesh wire fencing has emerged as one of the most practical solutions available. With its versatility, durability, and cost-effectiveness, mesh wire offers numerous benefits that cater to various fencing needs. This article dives into the different types of mesh wire for fences, their applications, advantages, and considerations for choosing the right one. Types of Mesh Wire Fencing 1. Chain Link Fencing Chain link fences are perhaps the most recognized form of mesh wire fencing. Constructed from galvanized steel wire, they provide a robust barrier while maintaining visibility. Ideal for residential properties, parks, and industrial sites, chain link fences are available in various heights and coatings, from galvanized to vinyl, to suit aesthetic preferences and environmental conditions. 2. Welded Wire Fencing This type of fencing consists of wire strands that are welded at their intersections, creating a grid pattern. Welded wire fences are renowned for their strength and resistance to rust, making them an excellent choice for agricultural use, including gardens, animal enclosures, and security perimeters. They can be found in various gauges, allowing for tailored strength depending on the requirements. 3. Barbed Wire Fencing Often used in agricultural settings, barbed wire fences incorporate sharp barbs at intervals along the wire to deter intruders and livestock. While effective for security and confinement, care must be taken with barbed wire, as it can pose risks to animals and people alike. 4. Electric Fencing Utilizing mesh wire that carries a safe electric current, this fencing type is commonly employed in agricultural settings to manage livestock movement. While it can effectively keep animals in or out, it requires careful installation and maintenance to ensure safety. Benefits of Mesh Wire Fencing - Durability Mesh wire fences are designed to withstand harsh weather conditions, from heavy winds to torrential rain. High-quality materials, such as galvanized steel, are resistant to rust and corrosion, providing long-lasting performance. - Versatility Available in various styles, gauges, and sizes, mesh wire fencing can cater to an array of applications, whether it’s for residential yards, sports facilities, or commercial perimeters . mesh wire for fence - Cost-Effectiveness Compared to other fencing materials, such as wood or vinyl, mesh wire is generally more affordable. Its installation and maintenance costs are also relatively low, making it an attractive option for budget-conscious homeowners and businesses. - Visibility Unlike solid fences, mesh wire allows for visibility, which can enhance the aesthetic appeal of a property while ensuring security. This is particularly beneficial in residential areas where homeowners desire a clear view of their surroundings. Considerations for Choosing Mesh Wire Fencing When selecting the right type of mesh wire fence, several factors should be taken into account - Purpose Consider what the primary use of the fence will be. Are you looking for security, privacy, or to contain pets or livestock? Understanding the purpose will help guide your choice. - Height and Gauge The height of the fence and the gauge of the wire are crucial factors for durability and security. Higher and thicker wire is typically more robust and is advisable for areas requiring extra protection. - Local Regulations Check with local zoning laws, as some areas have specific restrictions concerning the height and type of fencing allowed. - Installation There are various methods for installing mesh wire fencing, from DIY options to hiring professionals. Assess your comfort level and expertise before deciding on the installation method. In conclusion, mesh wire fencing is a versatile, durable, and cost-effective choice for many different applications. Its ability to provide security while maintaining visibility makes it an ideal solution for homeowners, businesses, and agricultural settings alike. By understanding the types of mesh wire available and considering your specific needs and local regulations, you can select the right fencing solution to safeguard your property effectively. Whether for protecting livestock, securing a garden, or simply delineating property lines, mesh wire fencing has proven itself to be a reliable investment for many.

- installing chicken wire fence******Installing Chicken Wire Fence A Comprehensive Guide When it comes to keeping chickens safe and secure, installing a chicken wire fence is one of the most effective ways to do so. Not only does it protect your feathered friends from potential predators, but it also keeps them from wandering off and getting lost. This guide will walk you through the steps of installing a chicken wire fence, ensuring that your flock remains safe and happy. Step 1 Planning Your Fence Before you start digging holes or hammering posts, it’s essential to plan your fence layout. Determine the size of the area you want to enclose and how many chickens you have. A basic rule of thumb is to allow at least 10 square feet of space per chicken to ensure they have enough room to roam and forage. Next, decide on the type of fence that works best for your needs. Chicken wire is the most popular choice due to its affordability and ease of installation. However, if predators in your area are particularly aggressive, you might want to consider using hardware cloth instead, as it offers more strength and durability. Step 2 Gathering Materials Once you have a clear plan, it’s time to gather your materials. Here’s a list of what you’ll need - Chicken wire or hardware cloth (depending on your choice) - Wooden or metal fence posts, which should be sturdy enough to withstand weather elements and animal pressure - Posthole digger or auger - Galvanized wire or fencing staples - Wire cutters - Hammer or staple gun (for fastening the chicken wire) - Measuring tape - Level Step 3 Installing the Fence Posts After gathering your materials, mark the locations where you will install the fence posts. It’s generally recommended to place the posts about 6 to 8 feet apart. Use a posthole digger or auger to dig holes that are at least 2 feet deep for stability. installing chicken wire fence Once the holes are dug, place the posts inside and fill the holes with soil or concrete for added support. Make sure to use a level to check that each post is straight. Allow the concrete to set if you’ve used it, typically for at least 24 hours, to ensure maximum stability. Step 4 Attaching the Chicken Wire Once your posts are securely in place, it’s time to attach the chicken wire. Start at one end of the fenced area and unroll the chicken wire along the fence line. Cut the wire to the appropriate length, leaving a little extra for overlap at the corners. To attach the chicken wire to the fence posts, use galvanized wire or fencing staples. If using staples, hammer them into the posts at regular intervals to ensure the wire remains taut. It’s crucial to keep the wire tight to prevent any gaps that could allow chickens to escape or predators to enter. Step 5 Adding a Gate An access point is essential for easy entry and care of your chickens. You can create a simple gate using additional wood or metal, attached with hinges. Ensure that the gate closes securely to prevent any chickens from escaping. A latch can provide added security by keeping the gate shut, particularly during the night when predators are most active. Step 6 Final Inspection After completing the installation, inspect your fence thoroughly. Look for any loose areas, gaps, or sharp edges that might pose a threat to your chickens. Make necessary adjustments to ensure the fence is as secure as possible. Conclusion Installing a chicken wire fence is a straightforward process that can greatly enhance the safety of your chickens. With proper planning and execution, you can create a secure environment for your flock to thrive. Remember to regularly check the integrity of the fence to maintain a safe haven for your chickens. Happy farming!

- Understanding the Features and Applications of Hexagonal Wire Mesh******Understanding Hexagonal Wire Mesh Applications and Benefits Wire mesh, a versatile material made of interconnected strands of wire, has been used in various industries for centuries. Among its many forms, hexagonal wire mesh stands out due to its unique design and beneficial properties. Hexagonal wire mesh, also known as hexagonal netting or chicken wire, features a honeycomb pattern that provides increased strength and stability compared to its square counterpart. In this article, we explore the characteristics, applications, and benefits of hexagonal wire mesh, highlighting why it remains a popular choice in various fields. Characteristics of Hexagonal Wire Mesh Hexagonal wire mesh is typically made from galvanized steel, stainless steel, or plastic-coated wire, ensuring durability and resistance to corrosion. The hexagonal pattern, with its six-sided openings, allows for a more efficient distribution of forces applied to the mesh. This design enhances the tensile strength of the material, making it suitable for use in areas where other mesh types may fail. Additionally, hexagonal wire mesh is often available in a variety of gauges (wire thicknesses) and opening sizes, allowing for flexibility to meet specific engineering and construction requirements. The mesh can be produced in different widths and lengths, providing further options for customization. The combination of its strength and flexibility makes hexagonal wire mesh a practical solution for many applications. Applications of Hexagonal Wire Mesh 1. Agriculture One of the most common uses of hexagonal wire mesh is in agricultural settings. It is extensively used for fencing to protect crops and livestock from predators. The hexagonal design allows for adequate visibility and air circulation while maintaining strong barriers. Farmers often use this type of mesh to construct chicken coops, rabbit enclosures, and other animal pens. 2. Construction and Landscaping In construction, hexagonal wire mesh serves multiple purposes. It is often used as a reinforcement material in concrete applications, providing additional strength and stability to structures. In landscaping, it is utilized to create retaining walls and erosion control systems, preventing soil erosion on slopes. 3. Horticulture In horticulture, hexagonal wire mesh is employed to support climbing plants and vines. The spacing of the mesh allows for optimal growth while providing guidance for plants to climb. Additionally, it is used in raised garden beds to keep pests away from plants. 4. Architectural Features Architects are increasingly incorporating hexagonal wire mesh into their designs for its aesthetic appeal and functionality. It is used in facades, trellises, and partitions, providing both structural support and elegance. The open design can create interesting light patterns and shadows, enhancing the visual experience of a space. wire mesh hexagonal 5. Industrial Applications In the industrial sector, hexagonal wire mesh is used for screening, security, and storage applications. It can be used in warehouses to create partitions, providing security while allowing visibility. Additionally, it is utilized in filtering systems where the mesh size can effectively trap unwanted particles. Benefits of Hexagonal Wire Mesh The unique design and construction of hexagonal wire mesh offer several benefits - Durability The materials used, coupled with the hexagonal pattern, contribute to its longevity, making it effective in both indoor and outdoor environments. - Versatility Hexagonal wire mesh can be used in a wide variety of applications, from agriculture to architecture. Its adaptability makes it a go-to choice for many industries. - Cost-Effectiveness Compared to other fencing and reinforcement solutions, hexagonal wire mesh is often more affordable, providing an economical option without sacrificing quality. - Ease of Installation The lightweight nature of hexagonal wire mesh allows for easier handling and installation, reducing labor costs and time on projects. - Environmental Sustainability Many hexagonal wire meshes are made from recycled materials, making them a sustainable choice for eco-conscious consumers. Conclusion Hexagonal wire mesh is a remarkable material that offers a fusion of strength, versatility, and aesthetic appeal. Its applications span a multitude of industries, making it an invaluable resource for farmers, builders, architects, and homeowners alike. As technology advances, we can expect to see even more innovative uses for hexagonal wire mesh, further solidifying its place as a foundational element in construction and agricultural practices around the world. With its combination of structural integrity and aesthetic potential, hexagonal wire mesh continues to be a favorite among professionals and DIY enthusiasts alike.

- Red negra de aves de corral******La Malla de Pollo Negra Beneficios y Usos La malla de pollo negra, un material ampliamente utilizado en la agricultura y la construcción, ha ganado popularidad en los últimos años debido a su versatilidad y eficacia. Esta malla, generalmente hecha de polipropileno o polietileno, es una opción ideal para diversos fines, desde la protección de cultivos hasta la construcción de cercas y la instalación en jardines. Beneficios de la Malla de Pollo Negra Uno de los principales beneficios de la malla de pollo negra es su resistencia. A diferencia de las mallas de colores claros, la malla negra tiende a ser más duradera, ya que su color oscuro ayuda a absorber el calor del sol, haciendo que los materiales sean menos propensos a desgastarse y descomponerse rápidamente. Esto la convierte en una opción ideal para aquellas áreas donde la exposición al sol es constante. La Malla de Pollo Negra Beneficios y Usos Usos Comunes black poultry netting La malla de pollo negra se utiliza en una variedad de aplicaciones. En la agricultura, se emplea para cubrir invernaderos y proteger cultivos de plagas. Esto no solo ayuda a mantener la sanidad de las plantas, sino que también promueve un ambiente de crecimiento óptimo. Del mismo modo, muchos jardineros utilizan la malla negra para crear barreras que protegen sus plantas de insectos y otros animales. En el ámbito de la construcción, la malla de pollo negra se utiliza como material de cercado. Es ideal para delimitar espacios y mantener a raya a animales no deseados. Su resistencia y durabilidad hacen que sea una opción preferida para cercas temporales y permanentes. Además, al ser ligera, es fácil de manipular y transportar, lo que la hace conveniente para proyectos de construcción de diferentes tamaños. Otro uso emergente de la malla de pollo negra es en la creación de telas de sombra. En climas calurosos, se puede usar esta malla para proporcionar sombra a las plantas, reduciendo el estrés del calor y mejorando el rendimiento de los cultivos. Su diseño permite que la luz solar penetre de manera suficiente, lo que es crucial para el crecimiento de las plantas. Conclusión La malla de pollo negra es un recurso invaluable tanto para agricultores como para jardineros y constructores. Con su capacidad de proteger eficientemente los cultivos, ofrecer durabilidad y ser versátil en diferentes aplicaciones, se ha convertido en un elemento esencial en la agricultura moderna. Ya sea para proteger un invernadero, crear una cerca o proporcionar sombra, la malla de pollo negra es una solución efectiva que ayuda a optimizar el crecimiento y la salud de las plantas, al tiempo que proporciona seguridad y versatilidad en la construcción. Si busca una opción confiable y duradera, la malla de pollo negra es, sin duda, una excelente elección.

- Iron Wire Reliable & Durable Solutions******Iron wire is more than just a simple engineering material; it is a versatile component that finds applications across diverse industries due to its remarkable strength, flexibility, and adaptability. Having spent years studying its properties and applications, I have developed a nuanced understanding of how iron wire can revolutionize various projects, thereby offering insights that any industry professional will find invaluable. One crucial aspect of iron wire is its strength-to-weight ratio, which makes it an ideal choice for construction and infrastructure projects. Unlike heavier metals, iron wire provides the necessary strength while remaining lightweight, effectively reducing the overall load on structures. This property is particularly beneficial in creating efficient designs for suspension bridges, towers, and lightweight frameworks . Construction experts have long relied on iron wire for its ability to withstand substantial load-bearing roles without the bulk associated with other metals. In landscaping and agriculture, iron wire offers versatility that practitioners deeply appreciate. From providing structural support for vines and plants to forming the backbone of trellises, iron wire facilitates optimal growth while blending seamlessly into the natural environment. Its durability in various climatic conditions ensures long-term utility, making it a smart investment for both small-scale gardeners and large agricultural operations. Further diving into its industrial applications, iron wire plays a pivotal role in manufacturing and production processes. Its malleability allows it to be drawn into fine wires or thicker gauges tailored for specific requirements, from crafting intricate jewelry to heavy-duty machinery components. This adaptability underscores its importance across different verticals, including automotive, aerospace, and electronics. iron wire Welding and metalworking professionals recognize iron wire for its reliable performance in joining and reinforcing metal structures. Its consistent diameter and composition are critical for achieving clean, strong welds, which are essential for the structural integrity of metallic constructions. This reliability ensures that iron wire remains a staple in workshops and factories around the globe. Moreover, iron wire's role in security applications cannot be overstated. Its use in fencing solutions provides both physical and psychological barriers, safeguarding properties while offering peace of mind. The ability to customize fences in various styles and configurations allows property owners to maintain aesthetic appeal without compromising on security. This characteristic has made iron wire a preferred choice for residential, commercial, and industrial security solutions. In the realm of arts and crafts, artisans come to appreciate the malleability and visual appeal of iron wire. Its ability to be shaped into intricate designs allows for creativity and innovation, resulting in unique art pieces and home decor items that stand the test of time. Artists and craft enthusiasts value iron wire for its balance between strength and flexibility, which facilitates the creation of both fine details and bold structures. In conclusion, iron wire's diverse applications highlight its unmatched combination of strength, flexibility, and resilience. Its role in construction, agriculture, manufacturing, security, and art not only underscores its practical value but also its ability to inspire creative solutions. As industries continue to evolve, iron wire remains a timeless resource that professionals can rely on to meet modern challenges. This authoritative perspective on iron wire should inspire you to consider its many possibilities in your next project.

- Understanding the Costs of Green Chain Link Fences for Your Property******Understanding Green Chain Link Fence Prices When it comes to home fencing options, chain link fences are revered for their durability, affordability, and versatility. Adding a touch of color to the traditional metal structure, green chain link fences have gained popularity among homeowners looking to balance functionality with aesthetics. This article delves into the factors that influence the prices of green chain link fences, providing you with a comprehensive understanding to help make informed decisions for your fencing needs. What is a Green Chain Link Fence? A green chain link fence is essentially the same as a standard chain link fence, but it is coated with a green vinyl or powder coating. This coating not only enhances the fence's visual appeal by blending it with natural surroundings but also increases the longevity of the product by providing additional protection against rust and corrosion. Factors Influencing Prices 1. Material Quality The quality of the materials used plays a vital role in determining the price of a green chain link fence. Higher-grade steel fence materials tend to be more expensive but provide increased durability and resistance to wear. 2. Coating Type The type of coating (vinyl or powder) and its thickness can affect the price. Thicker coatings typically offer better protection and aesthetics, but they can also raise the overall cost. 3. Height and Gauge Chain link fences come in various heights and gauges (the thickness of the wire). A taller fence or a thicker gauge will naturally cost more . Standard heights range from 3 to 12 feet, and many homeowners opt for a 4 to 6-foot fence for residential properties. 4. Length of the Fence The total length of the fence significantly impacts the overall cost. Longer fences require more materials, resulting in higher prices. 5. Installation Costs If you are planning to have the fence installed by a professional, labor costs will also need to be factored in. Installation prices can vary based on the complexity of the project, local labor rates, and additional features like gates or custom designs. green chain link fence prices 6. Location Geographic location can influence material and installation costs. Areas with a higher cost of living or those that require permits for fencing may see higher prices. 7. Accessories and Features Additional features such as gates, privacy slats, or extended warranties can contribute to the overall price. For example, incorporating a swinging gate can increase costs significantly. Average Cost Estimates To provide some tangible figures for prospective buyers, the average price for a green chain link fence typically falls between $10 to $20 per linear foot, including installation costs. However, costs can vary widely based on the factors outlined above. For instance, a basic 4-foot high green chain link fence may run about $12 per linear foot, while sturdier options or taller fences can exceed $20 per linear foot. In addition to the cost per linear foot, homeowners should also consider the initial investment in the fence itself versus the long-term value. Green chain link fences require less maintenance and have a longer lifespan compared to untreated wooden fences, making them a smart investment in the long run. Conclusion Green chain link fences present an attractive solution for homeowners in need of security and boundary definition without sacrificing visual appeal. Understanding the various factors that influence prices—such as material quality, height, installation costs, and location—will empower you to make better choices tailored to your specific needs. Before making a purchase, it’s advisable to obtain multiple quotes from different suppliers and installers to ensure fair pricing. Additionally, discussing your fencing needs with professionals can provide insights into the best options available that suit your budget and preferences. In the ever-evolving landscape of home improvement, investing in a green chain link fence could transform your outdoor space while ensuring durability and cost-effectiveness for years to come. With the right planning and research, homeowners can find the perfect fencing solution that not only meets their functional requirements but also complements their home’s design ethos.

- Konstruktion av trådnät för byggprojekt och dess tillämpningar******Byggnadsnät En Grundpelare i Konstruktionsindustrin Byggnadsnät, eller konstruktionsnät, är en viktig komponent inom byggindustrin som används för att verstärka och stabilisera olika strukturer. Dessa nät är tillverkade av ståltråd och finns i olika former, storlekar och tjocklekar, beroende på byggprojektets specifika behov. De har blivit en oumbärlig del av moderna byggmetoder, särskilt inom betongkonstruktion. Byggnadsnät En Grundpelare i Konstruktionsindustrin Det finns olika typer av byggnadsnät, varav de mest populära inkluderar masknät, som har stora öppningar och är idealiska för användning i väggar och golv, samt fibernät, som ofta används för att förstärka tunnare betongskikt. Valet av nät beror på grundläggande faktorer som den specifika konstruktionen, belastningskrav och miljöförhållanden. construction wire mesh I dagens klimat av ökande byggstandarder och hållbarhetsmål blir materialvalet allt viktigare. Byggnadsnät är oftast tillverkade av återvinningsbart stål, vilket gör dem till ett miljövänligt alternativ. Dessutom kan de appliceras på flera olika sätt för att optimera materialanvändning och minska spill. En annan aspekt att beakta är installationen av byggnadsnät. Det kräver noggrant arbete och expertis för att säkerställa att nätet placeras korrekt och att det verkligen uppfyller de strukturella kraven. Felaktig installation kan leda till allvarliga konsekvenser, inklusive byggfel och säkerhetsrisker. Därför är utbildning och erfarenhet en viktig del av processen för både byggare och ingenjörer. Sammanfattningsvis är byggnadsnät en grundläggande komponent i byggkonstruktion som erbjuder både styrka och hållbarhet. Med en ökande efterfrågan på högkvalitativa bygglösningar är det viktigt att branschen fortsätter att fokusera på innovation och utveckling av byggnadsnät. Genom att kombinera teknik med hållbarhetsprinciper kan byggnadsnät spela en avgörande roll i att forma framtidens strukturer, inte bara i Sverige utan världen över.

- stainless barbed wire******The Versatility and Importance of Stainless Barbed Wire Stainless barbed wire is a crucial material widely utilized in various industries, thanks to its durability and resistance to corrosion. Unlike traditional barbed wire, which is often made from galvanized steel, stainless barbed wire provides enhanced longevity and strength, making it an ideal choice for demanding environments. One of the primary uses of stainless barbed wire is in agricultural fencing. Farmers and ranchers have long relied on this type of fencing to protect their livestock and crops from predators and intruders. The sharp barbs placed at regular intervals create a formidable barrier that is difficult for animals and humans alike to breach. Additionally, because stainless steel is resistant to rust and degradation, farmers can depend on this fencing for years without the need for frequent replacements or repairs. In addition to agriculture, stainless barbed wire also finds extensive application in security fencing. Many industrial sites, military bases, and correctional facilities choose stainless barbed wire due to its strength and deterrent capabilities . The presence of such fencing acts as a psychological barrier, discouraging potential trespassers. When combined with other security measures, such as surveillance cameras and motion detectors, stainless barbed wire forms an effective perimeter that enhances overall security. stainless barbed wire Another significant benefit of stainless barbed wire is its low maintenance requirement. Traditional rusty wire can create safety hazards and necessitate regular painting or treatment to extend its lifespan. However, stainless barbed wire continues to maintain its structural integrity and appearance without much upkeep, allowing property owners to save time and resources. Moreover, the aesthetic appeal of stainless steel cannot be overlooked. In addition to its practical applications, many architects and designers incorporate stainless barbed wire into their projects to create contemporary and striking visual effects. By blending functionality with style, this material has proven to be not only utilitarian but also an artistic choice. In summary, the importance of stainless barbed wire spans across various sectors, from agriculture to security and even architecture. Its durability, low maintenance, and visual appeal make it an undeniable asset. As we continue to seek out materials that provide both strength and style, the use of stainless barbed wire is likely to expand, meeting the needs of modern society while ensuring safety and security.

- mesh fencing factory******The Importance of Choosing the Right Mesh Fencing Factory When it comes to securing your property, mesh fencing has proven to be one of the most effective solutions available. Its versatility, durability, and cost-effectiveness make it a popular choice for both residential and commercial applications. However, the quality and reliability of your mesh fencing largely depend on the factory from which it is sourced. Choosing the right mesh fencing factory is crucial to ensure you get a product that meets your needs and standards. First and foremost, the manufacturing process is key in determining the quality of the mesh fencing. A reputable mesh fencing factory should adhere to stringent quality control measures throughout production. This includes selecting high-grade materials, employing advanced manufacturing techniques, and ensuring thorough inspections at various stages of production. When you choose a factory that prioritizes quality, you can be confident that the mesh fencing you receive will withstand the test of time and adverse weather conditions. Another critical factor to consider is the customization options offered by the factory. Different projects have different requirements, and a one-size-fits-all approach often falls short . A reliable mesh fencing factory should provide customizable solutions that cater to specific needs, whether that be size, color, or design. This flexibility can be particularly important for unique residential landscapes or commercial premises that require a specific aesthetic or functional attributes. mesh fencing factory Cost is, of course, a significant consideration for any fencing project. However, it is essential to balance cost with quality. While cheaper options may seem appealing, they often compromise on durability and reliability. A quality mesh fencing factory may present a higher upfront cost, but the long-term savings associated with lower maintenance, replacements, and repairs can make it a more economical choice in the end. Moreover, investing in high-quality fencing can enhance the overall value of your property. Customer service is also an essential aspect of choosing the right mesh fencing factory. A factory that prioritizes customer relations will offer guidance throughout the buying process, from selecting the right type of fencing to answering post-installation queries. Look for a factory that provides comprehensive support, including installation advice, maintenance tips, and a clear warranty policy, to ensure you feel supported in your investment. Lastly, consider the factory's reputation in the industry. Researching reviews, testimonials, and case studies can provide valuable insight into the experiences of other customers. A well-regarded factory will have a history of satisfied clients who can vouch for the quality of the product and the integrity of the service. In conclusion, selecting the right mesh fencing factory is vital for ensuring a successful and long-lasting fencing solution. By focusing on quality manufacturing, customization options, cost-effectiveness, customer service, and reputation, you can make a well-informed choice that will protect your property and enhance its appeal for years to come. Investing time in this decision will pay off in the quality and functionality of your mesh fencing.

- PVC-coated wire mesh for durable construction******Understanding PVC Hardware Cloth The Versatile and Robust Material for Multiple Applications PVC hardware cloth, an innovative and versatile material, has carved a niche in various industries due to its unique blend of durability and functionality. This sturdy fabric, composed primarily of polyvinyl chloride (PVC) coated over a woven wire mesh, offers a robust solution for a myriad of applications. Hardware cloth, in its simplest form, is a wire mesh material with uniform openings. It gets its name from its traditional use in hardware stores for tasks like repairing screens or creating small animal enclosures. However, when PVC is introduced to the mix, it transforms into a material with expanded capabilities and a broader range of uses. The PVC coating on the hardware cloth imparts several advantageous properties. It provides a layer of protection against corrosion, making it ideal for outdoor applications where exposure to weather elements is inevitable. The PVC coating also enhances the cloth's resistance to chemicals, UV rays, and abrasion, extending its lifespan significantly. Moreover, this coating gives the cloth a smooth surface, reducing the risk of snags and injuries while handling. In construction, PVC hardware cloth is frequently employed as a reinforcement material in concrete works, providing additional strength and stability. Its permeability allows water and air to pass through, facilitating the curing process of concrete. It's also used in roofing applications for its ability to withstand harsh weather conditions and resist leakage. In agriculture, it serves as a perfect barrier for pest control, protecting crops from unwanted intruders without obstructing sunlight or air circulation In agriculture, it serves as a perfect barrier for pest control, protecting crops from unwanted intruders without obstructing sunlight or air circulation In agriculture, it serves as a perfect barrier for pest control, protecting crops from unwanted intruders without obstructing sunlight or air circulation In agriculture, it serves as a perfect barrier for pest control, protecting crops from unwanted intruders without obstructing sunlight or air circulation pvc hardware cloth . Furthermore, it can be shaped and cut to fit various sizes and forms, making it adaptable to different greenhouse designs. For DIY enthusiasts and homeowners, PVC hardware cloth is a go-to material for projects ranging from fence repairs to creating DIY furniture. Its lightweight nature makes it easy to handle, while its durability ensures longevity. In the manufacturing sector, it finds use in filter systems due to its ability to allow the passage of fluids while retaining solid particles. It's also utilized in industrial ventilation systems for its capability to block dust and other particulate matter. Despite its strength and resilience, PVC hardware cloth is surprisingly flexible, allowing it to bend and contour to irregular shapes without cracking or breaking. This adaptability, coupled with its cost-effectiveness, makes it a popular choice across various industries. In conclusion, PVC hardware cloth is more than just a simple mesh; it's a testament to the power of combining functionality with versatility. Its diverse applications, robustness, and ease of use make it a valuable asset in construction, agriculture, manufacturing, and countless other domains. As technology advances, the potential uses of PVC hardware cloth are likely to expand even further, cementing its position as a reliable and adaptable material in the modern world.

- Innovative Solutions for Hog Mesh Fencing in Agriculture and Livestock Management******The Hog Mesh Fence A Practical Solution for Livestock Management Hog mesh fences have gained popularity among farmers and landowners as a practical solution for managing livestock, especially hogs, in an efficient and safe manner. Comprised of strong, durable materials, these fences are designed to withstand the inherent challenges of farming environments while providing security and containment for animals. What is Hog Mesh Fence? A hog mesh fence, often referred to as a hog wire fence, is a type of fencing specifically designed to keep hogs and other livestock secure within a designated area. It typically consists of a series of vertical wires spaced closely together with horizontal wires creating a grid-like structure. This design prevents animals from escaping and deters predators from entering, making it an effective barrier for farming operations. The height and gauge of the wire can vary, allowing for customization based on the specific needs of the livestock and the terrain. For instance, a higher fence with stronger wire is advisable for larger animals or in areas where predatory threats are prevalent. Benefits of Hog Mesh Fencing 1. Durability and Longevity Hog mesh fences are built to last. Made from high-quality materials such as galvanized steel, they are resistant to rust, corrosion, and harsh weather conditions, which makes them a worthwhile investment for farmers. 2. Visibility and Aesthetics Unlike solid wood or vinyl fences, hog mesh fences provide visibility, allowing farmers to monitor their livestock easily . This characteristic also enhances the aesthetic appeal of the farm, giving it a more open and natural look. hog mesh fence 3. Cost-Effective Hog mesh fencing is often more affordable than other types of fencing, both in terms of initial installation and long-term maintenance. The low cost of materials combined with the ease of installation makes it a favored choice for many landowners. 4. Flexibility These fences are adaptable to various farming applications. They can be used to create pens for hogs, protect gardens from animals, or even serve as a boundary marker around pastures. 5. Ease of Repair In case of damage, repairing hog mesh fences is relatively straightforward. Individual sections can be replaced without the need to dismantle the entire fence, saving time and labor costs. Installation and Maintenance Installing hog mesh fencing requires proper planning and knowledge of the landscape. The first step involves assessing the perimeter that needs to be fenced and deciding on the appropriate height and gauge of mesh for the specific livestock. It's important to ensure that the fence is installed deep enough into the ground to prevent hogs from burrowing under it. Regular maintenance is crucial to ensure the longevity of the fence. This includes checking for wear and tear, tightening loose wires, and inspecting for rust or damage. Keeping the area around the fence clear of debris and vegetation can help prevent unwanted pests and improve the overall functionality of the fence. Conclusion In conclusion, hog mesh fencing represents a reliable and efficient solution for livestock management. Its robust construction, affordability, and flexibility make it a preferred choice among farmers and landowners. As the demand for effective livestock management solutions continues to grow, the hog mesh fence stands out as a testament to practical farming innovations that prioritize both the safety of animals and the operational efficiency of agricultural practices. Whether you are managing a small homestead or a large-scale farm, investing in a hog mesh fence can help ensure the well-being of your livestock while enhancing the overall productivity of your farming endeavors.

- Prijsinformatie voor gegalvaniseerd gelast draadnetwerk in Nederland******Prijsanalyse van Gep Galvaniseerd Lasdraad Gaas Gep galvaniseerd lasdraad gaas is een veelzijdig bouwmateriaal dat veel toepassingen kent in zowel de landbouw als de industrie. De prijs van dit soort gaas kan variëren afhankelijk van verschillende factoren, waaronder de kwaliteit van het staal, de galvanisatieproces, de specificaties van het gaas en de marktvraag. In dit artikel zullen we verschillende aspecten van de prijsstelling van gep galvaniseerd lasdraad gaas onderzoeken, evenals de impact van de markt op deze prijzen. Allereerst is het belangrijk om te begrijpen wat gep galvaniseerd lasdraad gaas precies is. Dit type gaas wordt vervaardigd door staaldraden die zijn gelast tot een netstructuur. Vervolgens wordt het gaas ondergedompeld in een zinkoplossing om het te beschermen tegen corrosie. Dit maakt het uiterst geschikt voor buitentoepassingen waar het blootgesteld kan worden aan weersomstandigheden. De dikte van de draden en de grootte van de openingen in het gaas kunnen variëren, wat invloed heeft op de prijs. Factoren die de prijs beïnvloeden Een van de grootste factoren die de prijs van gep galvaniseerd lasdraad gaas beïnvloeden, is de grondstofprijs van staal. Wanneer de staalprijs stijgt, stijgen ook de productiekosten van het gaas. Dit effect wordt vaak versterkt door de mondiale markten; bijvoorbeeld, als er een tekort aan staal is op de wereldmarkt, kan dit leiden tot hogere prijzen voor alle staalproducten, inclusief lasdraad gaas. Daarnaast heeft de galvanisatieproces tevens invloed op de kosten. Er zijn verschillende methoden voor galvanisatie, en sommige zijn duurder dan andere. De kwaliteit van het zink dat gebruikt wordt en de techniek die wordt toegepast, kunnen de prijs aanzienlijk verhogen. Goedkope galvanisatie kan resulteren in een kortere levensduur van het product, waardoor het op lange termijn misschien niet de beste keuze is. galvanized welded wire mesh prices Vraag en aanbod De vraag naar gep galvaniseerd lasdraad gaas fluctueert ook gedurende het jaar. In de bouwsector, vooral tijdens het voorjaar en de zomer, neemt de vraag vaak toe, wat kan leiden tot prijsstijgingen. Boeren kunnen ook seizoensgebonden behoeften hebben, afhankelijk van hun gewascyclus, wat eveneens invloed heeft op de vraag naar dit type gaas. Bovendien kunnen economische factoren zoals een recessie of een bloeiende economie ook invloed hebben op de vraag naar bouwmaterialen in het algemeen. Tijdens een economische neergang kan de vraag naar nieuwbouw en verbouwingen afnemen, wat resulteert in lagere prijzen. Aan de andere kant, in tijden van economische groei, kunnen de prijzen stijgen door een toename van de bouwactiviteit. Conclusie Samenvattend, de prijzen van gep galvaniseerd lasdraad gaas zijn onderhevig aan een breed scala aan factoren, van grondstofprijzen en productiemethoden tot seizoensgebonden vraag en algemene economische omstandigheden. Voor consumenten en bedrijven is het van essentieel belang om deze variabelen in overweging te nemen bij het aankopen van lasdraad gaas. Door goed geïnformeerd de markt te benaderen, kunnen ze betere aankopen doen en mogelijk kostenbesparingen realiseren. Het is altijd raadzaam om prijzen te vergelijken en bij verschillende leveranciers offertes aan te vragen voor het beste resultaat.

- vierkante kopspijkers voor houten vloeren******Vierkante Houten Spijkers voor Houten Vloeren Een Complete Gids Houten vloeren zijn een populaire keuze in veel Nederlandse huizen, dankzij hun esthetische uitstraling en duurzaamheid. Bij het installeren van houten vloeren komt een belangrijk aspect kijken het gebruik van de juiste bevestigingsmiddelen. Vierkante houten spijkers zijn een uitstekende optie voor dit doel. In dit artikel bespreken we alles wat je moet weten over vierkante spijkers voor houten vloeren, inclusief hun voordelen, toepassingen en installatie. Wat zijn vierkante spijkers? Vierkante spijkers zijn spijkers met een vierkante dwarsdoorsnede, wat ze onderscheidt van de meer traditionele ronde spijkers. Dit ontwerp zorgt ervoor dat ze beter gripen in het hout en zo een stevige verbinding creëren. Ze zijn vaak gemaakt van staal en zijn verkrijgbaar in verschillende maten en lengtes, afhankelijk van de specifieke toepassing. Voordelen van vierkante spijkers 1. Sterkte en stabiliteit Het belangrijkste voordeel van vierkante spijkers is hun vermogen om een stevige verbinding te creëren. Door hun ontwerp kunnen ze beter in het hout 'grijpen', waardoor ze minder kans hebben om los te raken in de loop der tijd. Dit is vooral belangrijk voor houten vloeren, die onderhevig zijn aan belasting en beweging. 2. Weerstand tegen splijten In tegenstelling tot ronde spijkers, die soms kunnen leiden tot splijten van het hout, zijn vierkante spijkers ontworpen om schade aan het materiaal te minimaliseren. Dit betekent dat je minder kans hebt op barsten of scheuren in je mooie houten vloer. 3. Esthetiek Voor sommige huiseigenaren is de esthetische uitstraling van de bevestigingsmiddelen belangrijk. Vierkante spijkers kunnen een rustiek en authentiek gevoel aan een houten vloer geven, wat goed past bij traditionele of ambachtelijke ontwerpen. Toepassingen van vierkante spijkers square head nails for wood floors Vierkante spijkers worden voornamelijk gebruikt voor het bevestigen van houten planken op een houten ondervloer. Ze zijn ideaal voor zowel massief houten vloeren als voor samengestelde houten vloeren. Daarnaast worden ze ook gebruikt in meubelmakerij en andere houtbewerkingstoepassingen waar sterke verbindingen noodzakelijk zijn. Installatie van vierkante spijkers Het installeren van vierkante spijkers kan aanzienlijke voordelen bieden, maar het is belangrijk om het juiste proces te volgen om ervoor te zorgen dat de spijkers effectief en veilig worden aangebracht 1. Voorboren In veel gevallen is het aan te raden om eerst te voorboren. Dit kan helpen om splijten en andere schade aan het hout te voorkomen. Kies een boor die iets smaller is dan de spijker om de perfecte pasvorm te garanderen. 2. Plaatsing Plaats de vierkante spijker in het voorgeboorde gat en gebruik een hamer of een spijkerpistool om deze in het hout te slaan. Zorg ervoor dat de spijker recht staat en dat je voldoende kracht uitoefent om deze volledig in het hout te duwen. 3. Afwerking Na het inslaan van de spijkers, kun je de koppen indien nodig inslaan en vervolgens het oppervlak van de vloer afwerken met een geschikte beits of vernis. Dit helpt om de spijkers te camoufleren en de algehele uitstraling van de vloer te verbeteren. Conclusie Vierkante houten spijkers zijn een geweldige keuze voor iedereen die houten vloeren installeert of renoveert. Hun unieke ontwerp biedt tal van voordelen, waaronder verbeterde grip, weerstand tegen splijten en een aantrekkelijke esthetiek. Door de juiste technieken toe te passen bij het installeren van deze spijkers, kun je ervoor zorgen dat je vloer niet alleen mooi is, maar ook duurzaam en stevig. Of je nu een nieuwe vloer legt of een bestaande vloer opknapt, overweeg om vierkante spijkers te gebruiken voor de beste resultaten.

- Metal Mesh Production Facility for High-Quality Customized Solutions and Services******The Importance of Metal Mesh Factories in Modern Industry In today's rapidly evolving industrial landscape, metal mesh factories play a crucial role in a variety of sectors, from construction to automotive, and even in the medical field. The versatility and functionality of metal mesh make it indispensable in countless applications, and understanding the operations of these factories can shed light on their significance in modern manufacturing. Metal mesh is a type of fabricated material created by weaving or welding together thin metal wires or strips to form a grid or net-like structure. Typically made from materials such as stainless steel, aluminum, or brass, metal mesh can be tailored to meet specific needs, ranging from simple screening to complex filters. This adaptability makes it a popular choice across various industries, including agriculture, aerospace, and environmental engineering. The Importance of Metal Mesh Factories in Modern Industry In the automotive industry, metal mesh is utilized for air and fluid filters, heat exchangers, and even sound-deadening applications. The automotive sector requires materials that can withstand high temperatures and pressure, and metal mesh provides the durability and resilience needed for these applications. Moreover, with the growing emphasis on sustainability, manufacturers are increasingly using recycled metals, further enhancing the eco-friendly credentials of metal mesh products. metal mesh factory The medical field has also recognized the benefits of metal mesh. It is commonly used in surgical applications, such as mesh implants for hernia repairs or bone fixation devices. The biocompatibility of certain metals, like titanium, makes them suitable for use in the human body, providing strength and support in various medical treatments. Furthermore, metal mesh is instrumental in the manufacturing of sterilization trays, ensuring that surgical instruments are cleaned and disinfected effectively. Moreover, metal mesh factories are pivotal in terms of economic impact. They not only create jobs directly within the manufacturing sector but also support a wide range of businesses across related industries. Suppliers of raw materials, logistics providers, and distributors all benefit from the operations of metal mesh factories. This interconnectedness fosters economic growth and development, particularly in regions where manufacturing plays a central role in the economy. Quality control is an essential aspect of metal mesh production. Factories implement rigorous testing protocols to ensure that the final product meets industry standards and client specifications. This commitment to quality is crucial, as many applications, particularly in the medical and aerospace sectors, require high levels of reliability and safety. Manufacturers must adhere to strict guidelines to achieve certifications, which further guarantees the integrity of their products. In conclusion, metal mesh factories are vital components of modern industry, providing essential materials that support a wide array of applications. From their contributions to construction and automotive manufacturing to their significance in healthcare, the importance of metal mesh cannot be overstated. As industries continue to evolve and adapt to new challenges, metal mesh will undoubtedly remain a foundational material, offering versatility, durability, and economic benefits that are essential for sustaining growth in today's competitive landscape. Investing in advanced manufacturing techniques and innovative designs will further enhance the capabilities of metal mesh factories, ensuring their relevance for years to come.

- razor wire fence for sale******Razor Wire Fence for Sale A Comprehensive Guide When it comes to security solutions, one of the most effective barriers available is a razor wire fence. This type of fencing is designed to deter unauthorized access and provide enhanced safety for both residential and commercial properties. If you’re in the market for a razor wire fence, this article will give you an insightful overview of its benefits, types, and what to consider before making a purchase. Understanding Razor Wire Fencing Razor wire, also known as concertina wire, consists of sharp, steel barbs attached to a steel wire strand. The twisted design of the wire and sharp barbs make it a formidable deterrent to intruders. Razor wire can be installed on top of conventional fences, walls, or as a standalone fence, creating a powerful barrier against trespassers. Advantages of Razor Wire Fencing 1. High Security The primary purpose of a razor wire fence is its ability to provide high security. Its sharp edges can cause injury to intruders, making it a less appealing option for those looking to breach a property. 2. Cost-Effective Compared to other high-security fencing solutions, razor wire is relatively affordable. This makes it an ideal choice for businesses and homeowners looking for effective security without breaking the bank. 3. Durability Razor wire is generally made from heavy-gauge steel, ensuring it can withstand various environmental factors without losing its effectiveness. 4. Visible Deterrent The intimidating appearance of razor wire serves as a visual warning, discouraging potential intruders from approaching your property. 5. Easy to Install Many types of razor wire systems are designed for straightforward installation, allowing property owners to secure their premises quickly and efficiently . Types of Razor Wire Fencing razor wire fence for sale 1. Concertina Wire This type is coiled and can expand to cover larger areas. It is often used along borders and can be deployed on various surfaces, including existing fences. 2. Barbed Wire While not as formidable as razor wire, barbed wire presents a decent security measure. It has barbs spaced along wire strands, though they are not as sharp or effective as razor wire sharp edges. 3. Razor Wire Fencing Panels These are pre-assembled panels that include razor wire integrated with standard fencing materials. They offer the combined benefits of a traditional fence and razor wire security. Factors to Consider Before Purchasing Razor Wire Fencing 1. Local Regulations Before investing in razor wire fencing, it's essential to check your local laws and regulations. In some areas, there may be restrictions regarding the height and type of fencing that can be installed. 2. Intended Use Consider the primary purpose of the fence. Are you looking to secure a commercial facility, a residential property, or a remote area? The intended use will help determine the type and height of the fence needed. 3. Installation Requirements While razor wire can be easy to install, ensure you are equipped with the tools and knowledge to do it safely. It's often advisable to hire professionals for installation, especially for large areas. 4. Maintenance Needs Depending on the environment, razor wire may require periodic maintenance to ensure it remains effective. Consider how much upkeep you are willing to commit to. 5. Aesthetic Concerns While security is the primary focus, consider how the fencing will look in your overall property design. You may want to combine razor wire with other types of fencing to create a more visually appealing solution. Conclusion Razor wire fencing represents one of the most effective security solutions available on the market. With its ability to deter intruders and offer a robust physical barrier, it is ideal for both residential and commercial properties. If you're considering purchasing razor wire fencing, keep in mind the various aspects mentioned—local regulations, intended use, installation, maintenance, and aesthetics. As you evaluate your options, you'll be better prepared to choose the right type of razor wire fence that meets your security needs while contributing positively to your property. Whether you decide to install it yourself or hire professionals, the investment in razor wire fencing will pay off in peace of mind and safety.

- Malhas de aves de capoeira******A Importância da Rede para Aves na Avicultura Moderna A avicultura é um setor vital da agricultura que se dedica à criação de aves, principalmente galinhas, patos, perus e codornas. Um dos componentes essenciais para a criação saudável e eficiente dessas aves é o uso de redes para aves, conhecidas como poultry mesh em inglês . Essas redes desempenham um papel fundamental na proteção, manejo e bem-estar das aves, contribuindo para um aumento na produtividade e na qualidade dos produtos avícolas. A rede para aves é um material projetado para fornecer um ambiente seguro e controlado para as aves criadas em liberdade. Feita geralmente de polietileno ou nylon durável, essa malha é utilizada para cercar áreas de criação, garantindo que as aves permaneçam em um espaço designado, ao mesmo tempo que as protege de predadores e outras ameaças. Um dos principais benefícios do uso de redes para aves é a proteção contra predadores. Aves como gaviões, raposas e até mesmo cães podem representar um grande risco para as aves em criação livre. A instalação de uma rede ao redor do espaço de criação não apenas impede a entrada desses predadores, mas também ajuda a minimizar o estresse das aves, que se sentem mais seguras em um ambiente protegido. Isso diretamente contribui para o seu bem-estar geral. Além disso, a rede para aves é um importante aliado no manejo das aves. Muitas vezes, os criadores necessitam controlar o acesso das aves a determinadas áreas, seja para permitir que se alimentem de forma adequada ou para proteger zonas de reprodução. Com o auxílio de redes, é possível delimitar essas áreas de forma prática, facilitando o manejo e garantindo que as aves tenham acesso aos recursos necessários para o seu desenvolvimento. poultry mesh Outro ponto relevante é o controle da saúde das aves. A rede para aves ajuda a manter um ambiente limpo e organizado, prevenindo a entrada de doenças que podem ser transmitidas por outros animais. Através de um espaço cercado e bem mantido, os criadores podem implementar melhores práticas de biosegurança, reduzindo a probabilidade de surtos de enfermidades que podem comprometer a produção. A sustentabilidade também é uma questão pertinente na avicultura moderna. Com o aumento da conscientização sobre práticas agrícolas sustentáveis, o uso de redes para aves pode contribuir para a criação de um sistema de produção mais responsável. Ao garantir que as aves possam viver em um ambiente saudável e seguro, os criadores conseguem produzir carne e ovos de qualidade, atendendo à crescente demanda do mercado por produtos sustentáveis e de origem responsável. Outro aspecto importante é a versatilidade das redes para aves. Elas podem ser utilizadas em diferentes tipos de criação, desde pequenos criadouros até grandes granjas comerciais. Independente da escala de produção, a implementação de redes para aves é uma solução acessível e eficiente para diversos tipos de avicultores. Por fim, a educação dos criadores sobre a importância do uso da rede para aves é fundamental. Investir em informação e treinamento pode levar a uma avicultura mais produtiva e sustentável. Cursos e workshops podem ser oferecidos para ensinar os benefícios da proteção, do manejo e da saúde das aves, promovendo melhores práticas na indústria. Em conclusão, a rede para aves, ou poultry mesh, é um componente indispensável na avicultura moderna. Suas funções de proteção, manejo e saúde das aves contribuem enormemente para o sucesso das criações. À medida que a demanda por produtos avícolas de qualidade continua a crescer, é essencial que os criadores adotem práticas que garantam o bem-estar das aves e a sustentabilidade da produção.

- weld mesh fence panels for sale******The Versatility of Welded Mesh Fence Panels for Sale Welded mesh fence panels have become an increasingly popular fencing solution due to their durability, versatility, and aesthetic appeal. Available in various sizes and configurations, these panels are ideal for a wide range of applications, from residential properties to commercial enterprises. If you are considering investing in welded mesh fence panels, this article will guide you through their advantages, uses, and where to find them for sale. What are Welded Mesh Fence Panels? Welded mesh fence panels are constructed from high-quality steel wires that are welded together at each intersection, creating a robust grid-like structure. This design not only ensures strength and stability but also makes it resistant to corrosion and rust when properly coated. The panels typically come in various heights, wire diameters, and mesh sizes, allowing for customization based on specific needs. Advantages of Welded Mesh Fence Panels 1. Durability One of the most significant advantages of welded mesh fence panels is their durability. The welding process creates a very strong bond between the wires, making the panels capable of withstanding harsh weather conditions and physical impacts. This resilience means that they can last for many years, providing long-term value and security. 2. Security Welded mesh fences offer an enhanced level of security for residential, commercial, and industrial properties. The robust structure is difficult to climb or cut, making it an effective deterrent against unauthorized access. 3. Visibility Unlike solid fences, welded mesh panels allow for visibility. This transparency can be particularly beneficial for commercial settings where visibility is crucial for security. Additionally, in residential areas, owners can maintain an open view of their surroundings while still enjoying the benefits of fencing. 4. Easy Installation Welded mesh fence panels are relatively straightforward to install. They can be mounted on various types of posts (metal, wooden, or concrete), and their lightweight design allows for easier handling and positioning during installation. 5. Aesthetic Appeal These panels are available in different finishes, including galvanized and powder-coated options. This variety allows homeowners and business owners to choose a style that complements their property while providing the necessary functionality. 6. Low Maintenance Compared to traditional fencing materials, welded mesh panels require less maintenance. A periodic cleaning and checking for any signs of wear are usually sufficient to keep them in good condition. Applications of Welded Mesh Fence Panels Welded mesh fence panels find use in numerous scenarios. Some common applications include weld mesh fence panels for sale - Residential Fencing Homeowners often choose welded mesh panels for backyard fencing, pet containment, or garden enclosures . - Commercial Fencing Businesses utilize these panels for perimeter security, storage yard enclosures, and to protect assets. - Industrial Sites Welded mesh panels are ideal for securing facilities, warehouses, and manufacturing plants, providing both visibility and security. - Agricultural Uses Farmers and ranchers use welded mesh fences for livestock containment and crop protection against wildlife. - Sports Facilities Many sports complexes use welded mesh fencing to create enclosures for fields, courts, and recreational areas. Where to Find Welded Mesh Fence Panels for Sale Finding high-quality welded mesh fence panels for sale is relatively easy. You can source them from various suppliers, including - Local Fence Supply Stores Many local retailers specialize in fencing materials and can offer personalized assistance. - Online Retailers Websites such as Amazon, Home Depot, or specialized fencing suppliers allow you to compare prices, materials, and customer reviews easily. - Manufacturers Purchasing directly from manufacturers can often lead to lower prices and customized solutions tailored to your needs. - Wholesale Distributors If you require large quantities, wholesale distributors may offer competitive pricing and bulk purchasing options. Conclusion Welded mesh fence panels are an excellent choice for anyone looking to secure their property with a durable, aesthetically pleasing, and versatile fencing option. With various applications and a range of benefits, these panels provide an effective barrier without compromising visibility or style. As you consider your fencing needs, be sure to explore the available options and choose the right welded mesh fence panels that suit your specific requirements.

- nails for lumber******The Importance of Nails for Lumber in Construction In the world of construction and woodworking, nails may seem like a simple, often overlooked element, but their role in securing lumber is vital to the integrity and durability of structures. Nails serve as the connective tissue among wood components, enabling builders to create sturdy frameworks and intricate designs. This article explores the importance of nails for lumber, types of nails commonly used, and the factors to consider when choosing the right nails for specific projects. Understanding Nails and Their Function Nails are small, pointed metal fasteners typically made of steel, stainless steel, or galvanized iron. They come in various shapes, sizes, and designs, each serving different purposes based on the materials being joined and the stresses they will face. While the primary function of a nail is to hold two pieces of wood together, its effectiveness depends on several factors, including the type of wood, nail length, gauge, and the environment in which it will be used. Types of Nails for Lumber There are numerous types of nails available in the market, but the following are some of the most commonly used in woodworking and construction 1. Common Nails These are the most basic type of nails and are generally used for framing. They have a smooth shaft and a flat head. Common nails are available in various lengths and thicknesses, making them versatile for different carpentry projects. 2. Box Nails Slightly thinner than common nails, box nails are ideal for lightweight lumber and are often used in applications where split wood can be a concern. Their design allows for less material displacement, reducing the risk of splitting. 3. Finishing Nails Used for trim work, cabinetry, and other projects requiring a clean finish, finishing nails have a small head that can be easily concealed. They are typically driven into the wood and countersunk to provide a smooth final appearance. 4. Framing Nails Known for their larger size and strength, framing nails are designed for heavier duty work like attaching wall studs. They are often used with pneumatic nail guns, making them ideal for fast-paced building environments. nails for lumber 5. Roofing Nails These nails come with a large flat head and are specifically designed for attaching roofing materials. They can be galvanized to resist corrosion caused by weather elements. 6. Decking Nails These are specifically designed for outdoor decks, often featuring coatings that prevent rust and promote durability against the elements. Factors to Consider When Choosing Nails The selection of nails for lumber is influenced by several important factors 1. Material Consider the type of wood being used and its properties. Hardwoods might require sturdier nails than softwoods. Additionally, the material of the nail should be compatible with the environment; for example, galvanized nails are recommended for outdoor applications due to their resistance to rust. 2. Length and Gauge The length of the nail should be appropriate for the thickness of the lumber being joined. Nails that are too short may not provide adequate holding power, while excessively long nails can cause wood to crack. The gauge, which indicates the nail’s thickness, also matters; thinner nails are less visible but may not hold as much weight. 3. Environmental Conditions Be mindful of the conditions in which the construction will take place. If the lumber is exposed to moisture, coastal areas require corrosion-resistant nails to prevent deterioration over time. 4. Application Method Consider whether you will be using a hammer or a nail gun. Certain nails are designed for specific types of application, and using the right type can significantly increase efficiency and effectiveness. Conclusion In conclusion, while nails might seem insignificant in the grand scheme of construction, they play a crucial role in ensuring the safety and longevity of structures. Understanding the different types of nails and their specific applications is essential for anyone involved in woodworking or construction. By selecting the right nails for lumber—considering factors such as material, length, gauge, and environmental conditions—builders can create solid, lasting constructions that stand the test of time. Whether you're a seasoned carpenter or a DIY enthusiast, paying attention to the details of nail selection can make a world of difference in the quality of your work.

- Prezzo di filo spinato gi******Il filo spinato in acciaio zincato è un prodotto ampiamente utilizzato per la protezione di aree residenziali, industriali e agricole. La sua principale funzione è quella di fungere da barriera contro intrusioni non desiderate, offrendo una soluzione efficace sia per la sicurezza che per la delimitazione dei confini. Tuttavia, uno degli aspetti più importanti da considerare quando si parla di filo spinato è il prezzo, che può variare notevolmente in base a vari fattori. . Un altro fattore che influisce sul prezzo è la lunghezza e il tipo di filo spinato. Esistono diverse tipologie di filo spinato, come quello a spirale o a nodi, e le dimensioni possono variare da un minimo di 50 metri a diversi chilometri. Acquistare in grandi quantità può comportare un risparmio, poiché i fornitori spesso offrono sconti per ordini di grandi dimensioni. gi barbed wire price Inoltre, anche la zona geografica può influenzare i prezzi. In alcune regioni, la domanda di filo spinato potrebbe essere più alta a causa di problemi di sicurezza, mentre in altre aree i prezzi potrebbero essere più competitivi. È sempre consigliabile confrontare i prezzi di diversi fornitori e prendere in considerazione anche le spese di spedizione. In conclusione, il costo del filo spinato in acciaio zincato dipende da diversi fattori come la qualità del materiale, il tipo e la quantità acquistata, e la localizzazione geografica. Fare una scelta informata e confrontare le opzioni disponibili può portare a un notevole risparmio e a un miglioramento della sicurezza.

- iron wire suppliers******Finding Reliable Iron Wire Suppliers When it comes to construction and manufacturing, iron wire is an essential component used in a variety of applications. From fencing and reinforcement to industrial projects, the demand for high-quality iron wire has increased significantly. As such, finding reliable iron wire suppliers has become crucial for businesses aiming to ensure the durability and strength of their products. Understanding the Types of Iron Wire Before seeking suppliers, it's essential to understand the different types of iron wire available in the market. The most commonly used types include galvanized iron wire, which is coated to prevent rust, and black iron wire, known for its sturdiness and pliability. Each type serves distinct purposes; for instance, galvanized wire is ideal for outdoor projects where exposure to moisture is a concern, while black wire is often used for tying and gripping applications. Understanding these differences helps buyers make informed decisions when choosing suppliers. Criteria for Selecting Iron Wire Suppliers 1. Quality Assurance The foremost criterion when selecting an iron wire supplier should be the quality of the wire. Suppliers should provide certifications that verify the grade of iron used, as well as compliance with industry standards. Quality assurance tests such as tensile strength, elongation, and corrosion resistance should also be taken into account. iron wire suppliers 2. Reliability and Reputation Researching a supplier’s reputation is vital. Look for reviews and testimonials from previous clients to gauge their reliability. A good supplier should have a proven track record of delivering quality products on time. 3. Range of Products Choose suppliers that offer a diverse range of iron wire products. This not only ensures that you can find what you need, but also gives you the option to source all your requirements from a single supplier, simplifying the procurement process. 4. Customer Service Excellent customer service is a significant factor that should not be overlooked. Suppliers who are responsive to inquiries and provide detailed product information are more likely to foster a good working relationship. Look for suppliers that prioritize customer satisfaction and are willing to accommodate special requests. 5. Pricing and Payment Terms While it's important to find quality products, pricing also plays a crucial role. Compare quotes from multiple suppliers to ensure you’re getting a fair deal. Additionally, inquire about payment terms, as flexible options may help manage cash flow effectively. Conclusion In conclusion, finding a reliable iron wire supplier is essential for various sectors, including construction, agriculture, and manufacturing. By understanding the types of iron wire available and assessing suppliers based on quality, reputation, product range, customer service, and pricing, businesses can make informed decisions that will positively impact their projects. Investing time in choosing the right supplier can lead to significant long-term benefits, ensuring that projects are completed efficiently and without unexpected delays or quality concerns. Whether you are working on a small-scale project or a large industrial venture, the right iron wire supplier can make all the difference.